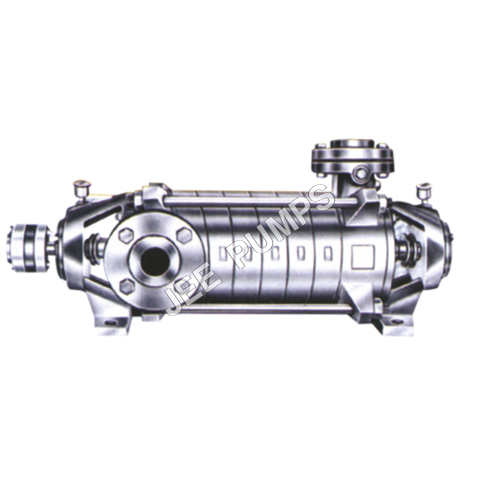

Industrial Centrifugal Process Pump

Product Details:

- Flow Rate Up to 500 m/h

- Theory Centrifugal Pump Theory

- Material Cast Iron, Stainless Steel

- Structure Single Stage, Back Pull-Out Design

- Suction Type End Suction

- Volute Type Single Volute

- Nozzle Location Top Discharge, Side Suction

- Click to View more

Industrial Centrifugal Process Pump Price And Quantity

- 15000.00 INR/Set

- 01 Set

Industrial Centrifugal Process Pump Product Specifications

- Top Discharge, Side Suction

- Direct Drive

- Up to 120C

- Centrifugal Pump Theory

- Cast Iron, Stainless Steel

- Up to 500 m/h

- End Suction

- 25 mm to 150 mm

- Single Stage, Back Pull-Out Design

- Electric

- Horizontal

- Single Volute

- Industrial Process, Chemical Transfer, Water Circulation, Effluent Treatment

- 1450/2900 RPM

- Up to 16 bar

Industrial Centrifugal Process Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Centrifugal Process Pumps

Our Centrifugal Process Pumps are worthy investment for valued clients because of lasting quality, excellent performance and longer serving ability. We ensure to users that our pump has zero design and production based errors because of advanced technology use. Our company takes high pride in serving the best pump that is noted for excellently handling a wide line of corrosive chemicals at different temperatures. This hydraulically balanced impeller promises superior efficiency and reduced power consumption. Chemical industries, sugar plants, heat exchangers, solvents transfer, food industries and automobile industries are some out of various application areas of this provided pump. Our offered Centrifugal Process Pumps is known for smooth running operation.

Features

- High quality base materials used in production uplifts quality standards of this pump.

- The low maintenance cost makes provided pump an ideal choice for clients.

- Increased efficiency, supreme design and flawless functioning adds value to offered product.

- This rugged construction of the pump enhances its ability to work in tough industrial conditions.

Product Details:

|

Capacity |

Up to 350 m3/hr |

|

Head |

Up to 150 mtr |

|

Temperature |

250 Deg C |

|

Speed |

Up to 3500 rpm |

|

Pressure |

Up to 15 kg/cm2 |

|

Discharge Size |

25 mm to 100 mm |

Engineered for Industrial Reliability

Our centrifugal process pumps set the benchmark for industrial durability with robust cast iron or stainless steel construction and precision mechanical seals or gland packing. The dynamically balanced enclosed impeller provides stable performance and minimal vibration, while heavy-duty bearings ensure consistent, uninterrupted operation.

Effortless Maintenance and Interchangeability

Designed with user convenience in mind, the pump features a back pull-out structure, easy maintenance protocols, and interchangeable components. This reduces downtime and simplifies routine servicing, allowing your facility to maintain continuous productivity with minimal intervention.

Adaptable for Multiple Applications

Whether you need a pump for chemical transfer, process liquid movement, or water circulation, this centrifugal pump delivers dependable service. Its capacity to handle temperatures up to 120C and pressures up to 16 bar means it excels in diverse industrial environments, including process industries, effluent treatment plants, and more.

FAQs of Industrial Centrifugal Process Pump:

Q: How does the enclosed, dynamically balanced impeller benefit the pumps performance?

A: The enclosed, dynamically balanced impeller reduces vibration, ensures smooth operation, and achieves efficient fluid movement, leading to longer service life and more consistent flow rates.Q: What installation position is recommended for this industrial pump?

A: This pump is designed for horizontal installation with a foot-mounted base, featuring top discharge and side suction for optimal pipeline configuration and performance.Q: When should a mechanical seal be chosen over gland packing?

A: A mechanical seal is recommended for applications requiring minimal leakage and handling of corrosive, hazardous, or high-temperature media, while gland packing may be suitable for less demanding conditions.Q: Where can this pump be used within industrial settings?

A: The pump is ideal for various industrial processes, including chemical transfer, water circulation, and effluent treatment, making it suitable for use in processing plants, utilities, and treatment facilities.Q: What is the process for routine maintenance of this centrifugal process pump?

A: Thanks to its back pull-out design and interchangeable components, routine maintenance involves shutting down the pump, removing the back cover, inspecting seals and bearings, and replacing worn components as needed without disturbing the main pipeline.Q: How does this pump handle priming and what is the recommended suction method?

A: This pump does not require self-priming, as it is intended for flooded suction installation. Ensuring the suction line and pump casing are always filled with liquid is recommended for reliable operation.Q: What are the benefits of the robust casing and corrosion-resistant materials used in this pump?

A: The robust casing and use of corrosion-resistant stainless steel or cast iron extend service life, reduce maintenance needs, and ensure compatibility with a wide variety of industrial liquids, thereby increasing operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free