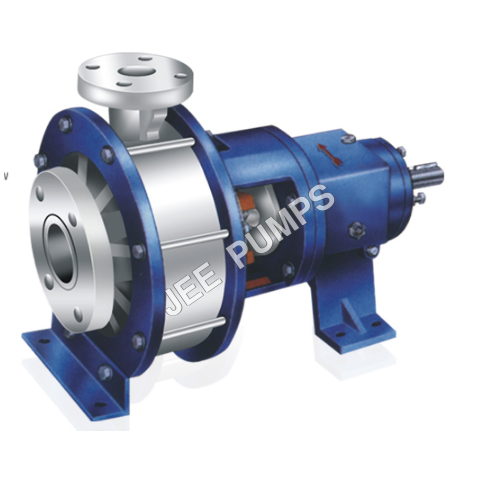

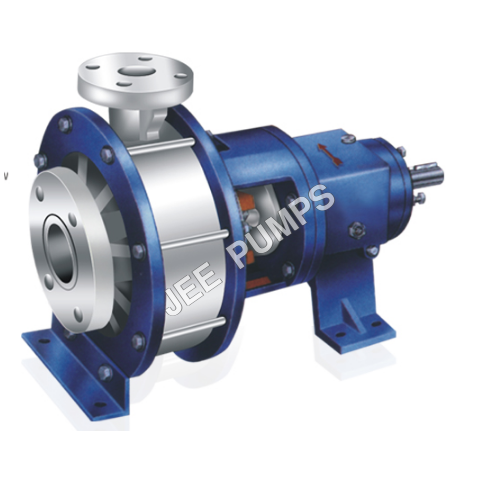

Industrial Open Impeller Pump

Product Details:

- Features Non-Clogging, Easy Maintenance, High Efficiency

- Voltage 220-440 V

- Speed 1440/2880 RPM

- Control System Manual / Automatic Start

- Noise Level Below 70 dB

- Head Size Up to 60 Mtrs

- Max Suction Up to 7 Mtrs

- Click to View more

Industrial Open Impeller Pump Price And Quantity

- 01 Set

- 6500 INR/Set

Industrial Open Impeller Pump Product Specifications

- Open Impeller Pump

- Up to 110 m/hr

- 50 mm (customizable)

- Single Stage

- Industrial

- 1 HP to 15 HP

- Base Plate Mounted

- 25 mm to 100 mm

- Mechanical Seal / Gland Packing

- High Pressure

- Up to 6 bar

- 1440/2880 RPM

- ISO 2858 / DIN 24256

- Single

- Non-Clogging, Easy Maintenance, High Efficiency

- 220-440 V

- Up to 80C

- Up to 110 m/hr

- 50/60 Hz

- Cast Iron / Stainless Steel

- Self / Manually priming

- Electric

- Chemical, Pharmaceutical, Food Processing, Agriculture

- Centrifugal Pump

- Manual / Automatic Start

- Below 70 dB

- Up to 60 Mtrs

- Up to 7 Mtrs

Industrial Open Impeller Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Open Impeller Pump

We offer Open Impeller Pump in which fluid enters from its eye where energy is added to the fluids using turning vanes. Then the fluids are directed to the discharge nozzle. This pump also includes a back plate and close clearance for preventing the inserted fluids from recirculating back to the eye. Our offered Open Impeller Pump is perfect option to be used for non sparkling and soft fluids. The impeller used in this pump can be easily adjusted for compensating wear. Ensures higher efficiency and does not require any disassembly. Also, it is rightly priced so that clients can buy it without thinking twice.

Features

- Consumes lesser space due to the compact size and require minimum operation time.

- Works without generating any noise.

- Higher capacity and better strength than any other pump.

- Innovative design and lower power consumption.

Specification

| Capacity | Up to 40 m3/hr |

| Temperature | 80 deg C |

| Speed | Up to 3500 RPM |

| Size | 25 mm to 65 mm |

| Pressure | Up to 5 kg / cm2 |

| Head | Up to 48 hrs |

Engineered for Diverse Industrial Needs

Designed to meet the rigorous demands of industries such as chemical processing, food manufacturing, pharmaceuticals, and agriculture, this Open Impeller Centrifugal Pump provides exceptional performance with high flow rates, non-clogging operation, and customizable features. It is built to ISO 2858/DIN 24256 standards, ensuring compatibility and reliability across a range of challenging applications.

Robust Construction and Superior Protection

The pump is constructed using high-grade cast iron or stainless steel options, with CNC-machined components, anti-corrosive coatings, and heavy-duty bearings for enhanced longevity. Its IP55-rated motor, epoxy coating, and flexible coupling ensure resilience against harsh environments while facilitating straightforward upkeep and dependable performance.

Effortless Installation and Serviceability

Designed for easy mounting on a base plate and available with both mechanical seal and gland packing options, this pump streamlines installation and routine maintenance. On-site support is available to ensure prompt assistance and minimize operational disruptions, providing peace of mind for your facility.

FAQs of Industrial Open Impeller Pump:

Q: How does the open impeller design benefit industrial applications?

A: The open impeller design reduces the risk of clogging, making it ideal for processes involving fluids with suspended solids or fibrous materials, which are common in chemical, food, and wastewater applications. This enhances reliability and minimizes downtime.Q: What materials are available for the impeller and shaft, and how do I choose the right ones?

A: Impeller materials include cast iron, bronze, SS304, and SS316, while shaft options comprise EN-8, SS304, and SS316. Choosing the right material depends on the fluids corrosiveness, temperature, and the specific industry requirements. Stainless steel options offer superior chemical resistance for aggressive fluids.Q: When should on-site support be requested for maintenance or troubleshooting?

A: On-site support should be requested whenever there are abnormal operating conditions, performance drops, or scheduled maintenance is due. Timely intervention ensures the pump remains efficient and prevents potential failures.Q: Where can the Industrial Open Impeller Pump be installed?

A: This pump is suitable for installation in industrial facilities such as chemical plants, food processing units, pharmaceutical manufacturing sites, and agricultural setups. It is designed for base plate mounting, ensuring stability and easy integration into existing systems.Q: What is the maximum temperature and flow rate this pump can handle?

A: The pump is engineered to handle working temperatures up to 80C and achieve a maximum flow rate of up to 110 m/hr, making it suitable for demanding industrial processes.Q: How do manual and automatic control systems differ in operation?

A: Manual control allows operators to start and stop the pump directly, while automatic control utilizes sensors and control panels for unattended operation, optimizing efficiency and safety based on process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM