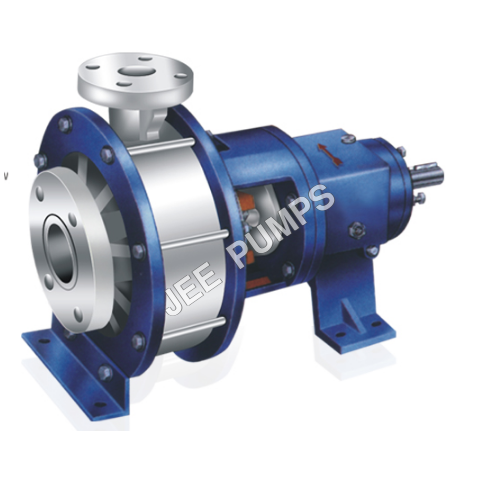

Industrial Polypropylene Process Pump

Product Details:

- Head Size Up to 24 meters

- Flow Rate Up to 12 m3/hr

- Discharge Pressure Max 3 kg/cm

- Theory Centrifugal Pump

- Frequency 50/60 Hz

- Working Temperature Up to 80C

- Mounting Type Base plate mounted

- Click to View more

Industrial Polypropylene Process Pump Price And Quantity

- 22000.00 INR/Set

- 01 Set

Industrial Polypropylene Process Pump Product Specifications

- Corrosion resistant, Leak-free operation, Maintenance friendly

- <75 dB

- DOL/Star Delta Starter

- ISO 5199 / DIN 24256

- As per model specification

- Up to 3 meters

- Electric

- 40 mm x 32 mm

- 220 - 415 V

- Up to 12,000 LPH

- 2850 RPM

- Chemical Process, Acid Transfer, Effluent Management

- Base plate mounted

- Up to 80C

- Industrial chemical and process pumping

- Centrifugal Pump

- 50/60 Hz

- Single-stage, horizontal

- Mechanical Seal

- Polypropylene

- Max 3 kg/cm

- Up to 12 m3/hr

- Process Pump

- Up to 3 kg/cm

- Up to 24 meters

- Self priming or non-self priming

- 0.5 HP - 5 HP

- Horizontal suction

Industrial Polypropylene Process Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Our top grade Polypropylene Process Pumps are highly reliable, they are perfect for varied application areas demanding corrosion proof as well as maintenance free pumping. These process pumps wins the trust of many with their ability to handle hazardous chemicals and substances that may be corrosive in nature without sustaining any damages. The quality of these Polypropylene Process Pumps is applauded worldwide owing to its compliance to the international standards and guidelines. The durable service life of the offered process pumps also attracts a huge clientele towards our pump gamut. These unique variety of chemical process pumps are also popular for their amazing efficiency.

Features

- Our pumps have no defects that hinders with their performance or reliability

- Our pumps are designed carefully as per the latest standards and demands of clients

- Our pumps are made using quality parts and materials

- Our pumps are assured to be highly corrosion resistant

Specification

| Capacity | Up to 50 m3/hr |

| Head | Up to 45 mtr |

| Temperature | 80 deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 4.5 kg/cm2 |

| Discharge Size | 25 mm to 50 mm |

Superior Chemical Resistance & Durability

Manufactured from high-grade polypropylene and featuring a corrosion-resistant SS 316 shaft, this process pump withstands aggressive chemicals and harsh industrial environments. The mechanical seal design further ensures leak-free, continuous operation, while the robust ball bearing system and IP55 motor protection guarantee reliable, long service life even under demanding conditions.

Flexible Application & High Performance

The pump delivers up to 12 m/hr flow, supports liquid pH levels from 1 to 14, and handles working temperatures up to 80C, making it versatile for various industrial processes. With options for single or three-phase operation and multiple priming types, it adapts to diverse installation requirements and process needs.

User-Friendly Maintenance & Operation

Engineered for easy handling, the pump features horizontal suction, self-priming or non-self-priming capability, and base plate mounting for straightforward installation and servicing. Its low noise level (<75 dB), low vibration, and maintenance-friendly construction reduce downtime and operational costs.

FAQs of Industrial Polypropylene Process Pump:

Q: How does the polypropylene process pump handle corrosive liquids?

A: The pump is constructed from high-quality polypropylene with a SS 316 shaft and mechanical seal, providing excellent resistance to corrosive chemicals and a wide pH range (114). This makes it ideal for handling acids, alkalis, and aggressive solutions.Q: What maintenance is required for this industrial pump?

A: Routine maintenance mainly involves checking the mechanical seal, lubricating the heavy-duty ball bearings, and ensuring the shaft alignment. Due to its corrosion-resistant materials and leak-free design, maintenance is typically straightforward and infrequent.Q: When should I choose self-priming versus non-self-priming models?

A: Self-priming models are recommended when the pump needs to lift liquid from depths of up to 3 meters, such as from underground tanks. Non-self-priming variants are suitable for installations where the pump is flooded or mounted below the liquid source.Q: Where can this pump be installed in an industrial facility?

A: The pump can be base plate mounted in various process areas, including chemical plants, effluent treatment units, and acid transfer stations. Its IP55 protection and heavy-duty construction make it suitable for both indoor and sheltered outdoor environments.Q: What are the key benefits of using this process pump in chemical applications?

A: Key advantages include corrosion resistance, wide pH handling capability, operational reliability, low maintenance, and leak-free operation. These features ensure resilient performance in demanding industrial chemical and process pumping tasks.Q: How does the control system operate the motor?

A: The pumps motor can be controlled using a DOL (Direct-On-Line) or Star Delta Starter, providing flexibility for both single and three-phase installations as per your facility requirements.Q: What standards and certifications does the pump meet?

A: This pump is engineered in compliance with ISO 5199 and DIN 24256 standards, ensuring high quality, safety, and reliable performance in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free