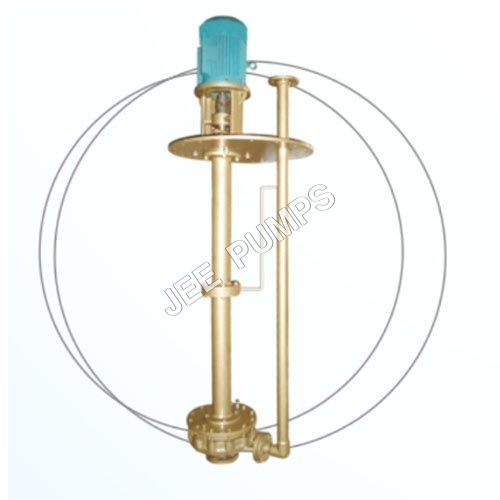

Industrial Volatile Liquid Transfer Pump

Product Details:

- Discharge Pressure Max 2 Bar

- Theory Centrifugal Pump

- Working Temperature -10C to 80C

- Caliber 25 mm

- Features Corrosion resistant, Heavy Duty, Leak-proof operation

- Max Suction 6 m

- Inlet/Outlet 1 inch / 1 inch

- Click to View more

Industrial Volatile Liquid Transfer Pump Price And Quantity

- 1 Set

Industrial Volatile Liquid Transfer Pump Product Specifications

- Self Priming

- 50 LPM

- Monoblock Design

- 50/60 Hz

- 20 meters

- 1 HP

- 2800 RPM

- Low Noise (<75 dB)

- Industrial Liquid / Chemical Transfer

- Baseplate / Stationary

- Volatile Liquid Transfer Pump

- 220V / 380V, 50/60 Hz

- Electric

- 1 inch / 1 inch

- Manual/Automatic Start-Stop

- 6 m

- Positive Suction

- Volatile Liquid, Acid, Solvent Transfer

- 25 mm

- Corrosion resistant, Heavy Duty, Leak-proof operation

- -10C to 80C

- Centrifugal Pump

- Stainless Steel / Cast Iron

- 2 Bar

- ISO 9001:2015

- 3000 LPH

- Max 2 Bar

- Mechanical Seal

Industrial Volatile Liquid Transfer Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Volatile Liquid Transfer Pump

Excellent working of our Volatile Liquid Transfer Pump is a result of employing advanced production methods. We believe in quality being the primary yet imperative necessity of any product. Hence, we ensure to customers related to serving singularly the best pump that is lasting in use and fantastic in terms of performance. The non-clogging feature allows it to perform with high excellency. The strong built of the pump makes it extremely appropriate for use in rough industrial settings. Provided Volatile Liquid Transfer Pump passes through different quality based tests prior delivery. This is done to provide clients the best value of their money.

Features:

- This pump boasts of using consuming less space and minimal time in operation

- Provided pump is highly efficient and witnesses zero breakdowns.

- Longer service life, high capacity and great strength are crucial traits of this pump.

- This pump operates without creating producing high noise.

Specification

|

Length |

Up to 4 mtrs |

|

Motor Horsepower |

20 - 140 HP |

|

Head |

15 to 50 m |

|

Motor Phase |

Three Phase |

|

Brand |

Jee pumps |

|

Number Of Stages |

Single-stage Pump |

|

Capacity |

Up to 350 m3/hr |

|

Model Number/Name |

JVSP |

|

Temperature |

Up to 160 deg C |

|

Speed |

Up to 3500 RPM |

|

Pressure |

Up to 10 kg / cm2 |

Efficient Transfer of Volatile Liquids

Designed specifically for the movement of acids, solvents, and volatile liquids, this pump combines a closed impeller with a self-priming mechanism for rapid, reliable operation. Its positive suction capability and mechanical seals prevent leaks, ensuring both operator safety and environmental protection during demanding industrial applications.

Durability Meets Performance

Crafted from stainless steel and cast iron, the pumps heavy-duty monoblock structure and IP55-protected, F-class insulated motor provide longevity even in aggressive environments. With a flow rate of 50 LPM and a head size of 20 meters, it maintains consistent performance without compromising energy efficiency.

Versatile Installation & Simple Operation

Offering both manual and automatic start-stop controls and flexible baseplate installation, this pump adapts easily to diverse industrial setups. Its low operational noise (<75 dB) and compact design enable seamless integration into new or existing systems, making it practical for distributors, exporters, manufacturers, wholesalers, and traders.

FAQs of Industrial Volatile Liquid Transfer Pump:

Q: How does the self-priming feature benefit industrial users of this volatile liquid transfer pump?

A: The self-priming mechanism enables the pump to automatically evacuate air from the suction line, allowing for quick startup without manual priming. This minimizes downtime and accelerates the liquid transfer process, particularly useful in industrial settings handling volatile substances where efficiency and safety are crucial.Q: What types of liquids can this pump transfer safely?

A: This centrifugal pump is engineered to handle volatile liquids such as acids, chemicals, solvents, and other industrial fluids. Its corrosion-resistant stainless steel and cast iron construction, along with leak-proof mechanical seals, ensures secure transfer without risk of content contamination or pump degradation.Q: When is on-site support available for installation or maintenance?

A: On-site support is provided as part of the service offering for installations, troubleshooting, and maintenance. Availability depends on your location in India and can be scheduled by contacting the supplier or distributor; prompt assistance ensures reliable pump operation and minimal downtime.Q: Where can the pump be installed within an industrial facility?

A: This pump is designed for horizontal baseplate or stationary mounting, making it adaptable to a range of installation points such as process lines, chemical transfer stations, or storage tank connections. Its compact structure supports versatile placement in both confined and open plant layouts.Q: What is the typical process for industrial liquid transfer using this pump?

A: The process involves connecting the inlet and outlet (each 1 inch in diameter, 25 mm caliber) to the source and destination tanks, powering the pump (220V/380V; 50/60 Hz), and starting operation via manual or automatic controls. The positive suction draws liquids effectively from up to 6 meters below, ensuring steady flow up to 50 LPM with a discharge pressure of up to 2 bar.Q: How does the corrosion resistance and leak-proof operation extend the pumps lifespan?

A: The use of stainless steel and cast iron materials, along with robust mechanical seals, resists chemical attack and prevents leaks. This safeguards internal components from aggressive fluids, reduces maintenance frequency, and prolongs the service life, supporting lower ownership costs for industrial users.Q: What are the main benefits of choosing this monoblock design pump for volatile liquid handling?

A: Key benefits include energy-efficient centrifugal operation, heavy-duty build, self-priming for operational readiness, minimal noise emissions, and compact installation. Additionally, compliance with ISO 9001:2015 and on-site support reflect commitment to quality and operational excellence for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM