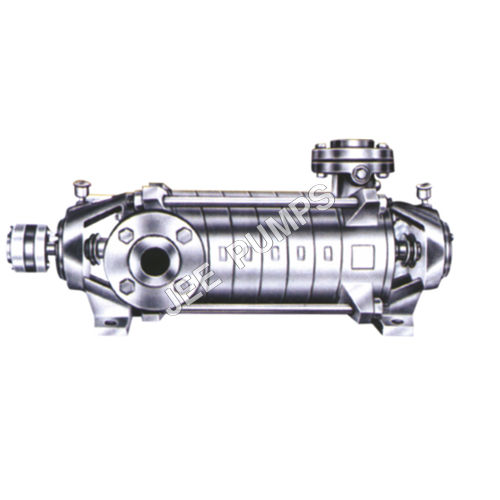

High-Pressure Centrifugal Multistage Pump

22000.00 INR/Set

Product Details:

- Theory Centrifugal

- Flow Rate Up to 500 m/h

- Material Cast Iron, Stainless Steel, Bronze

- Structure Horizontal Multistage

- Suction Type Single / Double Suction

- Volute Type Multistage

- Nozzle Location End Suction, Top Discharge

- Click to View more

X

High-Pressure Centrifugal Multistage Pump Price And Quantity

- 22000.00 INR/Set

- 01 Set

High-Pressure Centrifugal Multistage Pump Product Specifications

- Multistage

- Up to 60 Bar

- Boiler Feed, Water Supply, Fire Fighting, Industrial Process

- Horizontal Multistage

- Centrifugal

- Electric Motor

- Horizontal

- 1450/2900 rpm

- End Suction, Top Discharge

- Up to 500 m/h

- 50 mm to 150 mm

- Up to 120C

- Single / Double Suction

- Cast Iron, Stainless Steel, Bronze

High-Pressure Centrifugal Multistage Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Technical Specification

Capacity | Up to 80 m3/ hr |

Head | Up to 300 mtr |

Temperature | Up to 120 deg C |

Speed | Up to 3500 RPM |

Pressure | Up to 30 kg/cm2 |

Material of Construction | Cast Iron, Bronze, Steel |

Discharge Size | 32 mm to 80 mm |

Designed to Exceed Performance Standards

The multistage pump complies with global design standards including ASME, ISO, and DIN. Its enclosed impeller design and flexible selection between single or double suction ensure operational efficiency and versatility. Coupling this with a sturdy baseplate-mount structure and robust shaft material, the pump meets the rigorous expectations of diverse industrial applications.

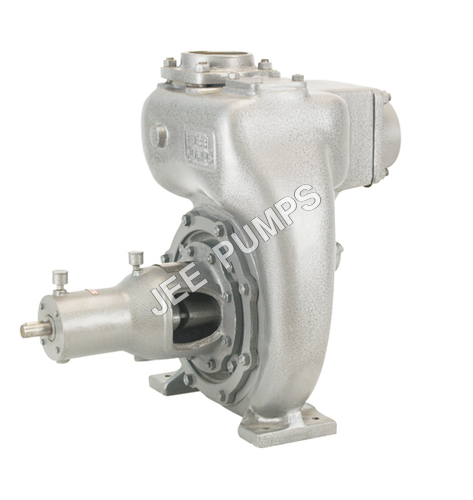

Tailored for Various Industrial Applications

Engineered for applications like boiler feed, fire fighting, and industrial water supply, this pumps adaptability is its strength. The wide range of inlet and outlet diameters (50150 mm), multistage construction, and choice of air or water cooling allow customization to specific needs. Protection class IP55 ensures safe operation in challenging environments.

Low Maintenance and Efficient Operation

Utilizing either a mechanical seal or gland packing, as well as antifriction ball bearings, this pump promises smooth and low-maintenance operation. The flexible coupling reduces vibration and wear, while the option for air or water cooling maintains optimal efficiency during continuous usage, making it a dependable, cost-effective solution.

FAQs of High-Pressure Centrifugal Multistage Pump:

Q: How does the multistage design enhance the pumps performance in high-pressure applications?

A: The multistage design incorporates multiple enclosed impellers (210 stages), each incrementally boosting the pressure. This setup enables the pump to handle high-pressure needsup to 60 Barmaking it ideal for boiler feed, fire fighting, and industrial water processes.Q: What are the advantages of using a mechanical seal versus gland packing in this pump?

A: A mechanical seal offers superior leak prevention and lower maintenance requirements. Gland packing, while more traditional, is cost-effective and suitable for less demanding applications. Both options allow you to select what best fits your process and maintenance preferences.Q: When should I choose air cooling versus water cooling for this pump?

A: Air cooling is suitable for ambient temperature operations and when water supply is limited. Water cooling is recommended for higher temperature processes or continuous heavy-duty use, as it more effectively dissipates heat and extends the life of critical components.Q: Where can this high-pressure multistage pump be installed?

A: This pump is baseplate-mounted with a horizontal shaft orientation for stable installation in industrial facilities such as boiler rooms, water treatment plants, or fire-fighting systems. The protective IP55 class also ensures reliable operation in challenging or wet environments.Q: What is the typical process for priming this pump?

A: Depending on the model, the pump offers self-priming and non-self-priming options. For self-priming models, the pump evacuates air from the suction line automatically, simplifying initial startup. Non-self-priming units require manual priming before operation.Q: How can businesses benefit from the flexible coupling and antifriction ball bearings in this pump?

A: Flexible coupling minimizes transmission shocks and misalignments between the pump and motor, reducing mechanical stress and enhancing service life. Antifriction ball bearings further reduce operational friction, lowering energy consumption and ensuring smooth performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Centrifugal Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM