Industrial Priming Chambers Pump

Product Details:

- Size Multiple sizes available as per pump capacity

- Shape Cylindrical chamber with flanged connections

- Part Type Priming Chamber

- Material Cast Iron

- Usage Used for priming centrifugal pumps

- Application Industrial pumping systems, irrigation installations

- Theory Air is removed from the pump casing to facilitate liquid flow

- Click to View more

Industrial Priming Chambers Pump Price And Quantity

- 01 Set

Industrial Priming Chambers Pump Product Specifications

- Air is removed from the pump casing to facilitate liquid flow

- Multiple sizes available as per pump capacity

- Priming Chamber

- Cylindrical chamber with flanged connections

- Used for priming centrifugal pumps

- Industrial pumping systems, irrigation installations

- Cast Iron

Industrial Priming Chambers Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

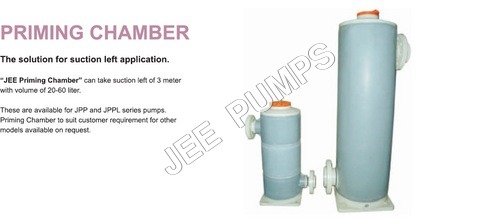

Recognized among the distinctive organizations, we are involved in manufacturing, supplying and exporting excellent quality Priming Chambers Pump . We are backed with proficient professionals, who manufacture these chambers employing latest technology. Owing to their excellent performance and longer service life, our chambers are highly applauded in the market. Our chamber is catering to the demands of various industries. To fulfill the varied industrial demands, we offer this Priming Chambers Pump in various sizes and specifications.

Features :-

- Compact design

- Easy installation

- Less noise & vibration

- Easy maintenance

Specification :

The solutions for suction left application :

- "JEE Priming Chamber" can take suction left of 3 meter with volume of 20-60 liter.

- Priming Chamber are available for all M.O.C. as per customer requirement

Technical Specification

Suction Size | 3 meter |

Usage/Application | Industrial |

Material | Mild Steel |

Temperature | Up to 150 Degree C |

Motor Horsepower | 3 HP |

Motor Phase | Three Phase |

Volume | 20-60 Liter |

Surface Finish | Paint Coated |

Engineered for Robust Industrial Use

With its cast iron construction and corrosion-resistant finish, the priming chamber is built to withstand the rigors of industrial environments. The cylindrical design and available color options of blue or black make it a practical and professional addition to any pump system.

Versatile & Reliable Operation

This priming chamber is designed for both horizontal and vertical mounting, offering flexibility during installation. Its flanged end connections allow for sturdy attachment, making it compatible with various centrifugal pumps across multiple industry segments.

FAQs of Industrial Priming Chambers Pump:

Q: How does an industrial priming chamber function in a pumping system?

A: An industrial priming chamber removes air from the casing of a centrifugal pump, creating the necessary vacuum for liquid flow and ensuring efficient pump operation from startup.Q: What are the primary benefits of using a corrosion-resistant priming chamber?

A: Corrosion-resistant coatings extend the lifespan of the chamber by protecting it against harsh chemicals and environmental factors commonly present in industrial applications.Q: When should a priming chamber be installed in a pump system?

A: A priming chamber should be installed whenever theres a need to quickly remove air from the pump casing, especially in systems where maintaining a constant liquid flow is crucial, such as in irrigation or industrial water distribution.Q: Where can this priming chamber be utilized effectively?

A: The chamber is ideal for use in industrial pumping systems, irrigation setups, and commercial water management, serving distributors, exporters, manufacturers, and suppliers across India.Q: What is the typical process for installing the priming chamber?

A: Installation involves attaching the chamber in either a horizontal or vertical orientation using the flanged ends, connecting it securely to the pumps suction line to ensure effective priming.Q: How does the choice of mounting type affect the performance?

A: Choosing between horizontal or vertical mounting provides flexibility for site-specific requirements without affecting the chambers priming performance.Q: What advantages come with using a flanged connection for the priming chamber?

A: Flanged ends enable easy and secure connections with the pump system, promoting a quick installation and reliable leak-proof operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM