Industrial Rotary Gear Pumps

24500.00 INR/Piece

Product Details:

- Noise Level Low

- Control System Manual / Automatic

- Max Suction 5 m

- Frequency 50 Hz / 60 Hz

- Discharge Pressure Up to 10 Bar

- Flow Rate Up to 800 LPH

- Mounting Type Base Plate Mounted

- Click to View more

X

Industrial Rotary Gear Pumps Price And Quantity

- 1 Piece

- 24500.00 INR/Piece

Industrial Rotary Gear Pumps Product Specifications

- 5 m

- Mechanical Seal / Gland Packing

- API, IS Standards

- Low

- Manual / Automatic

- Chemical, Petrochemical, Pharmaceutical & Oil Industries

- Up to 10 Bar

- Up to 800 LPH

- 50 Hz / 60 Hz

- Industrial Oils, Fuels & Chemicals Transfer

- Rotary Gear Design

- Rotary Gear Pump

- 0.5 to 5 HP

- Positive Suction

- Cast Iron / Stainless Steel / Bronze

- Base Plate Mounted

- Up to 10 Kg/cm

- Standard sizes available

- Suitable for Oil, Diesel, Chemicals

- Rotary Positive Displacement

- 230V / 415V

- Up to 800 LPH

- Up to 10 Bar

- 1440 RPM

Industrial Rotary Gear Pumps Trade Information

- AHMADABAD

- Western Union, Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 50 Piece Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- 3.5 % extra

- All India

Product Description

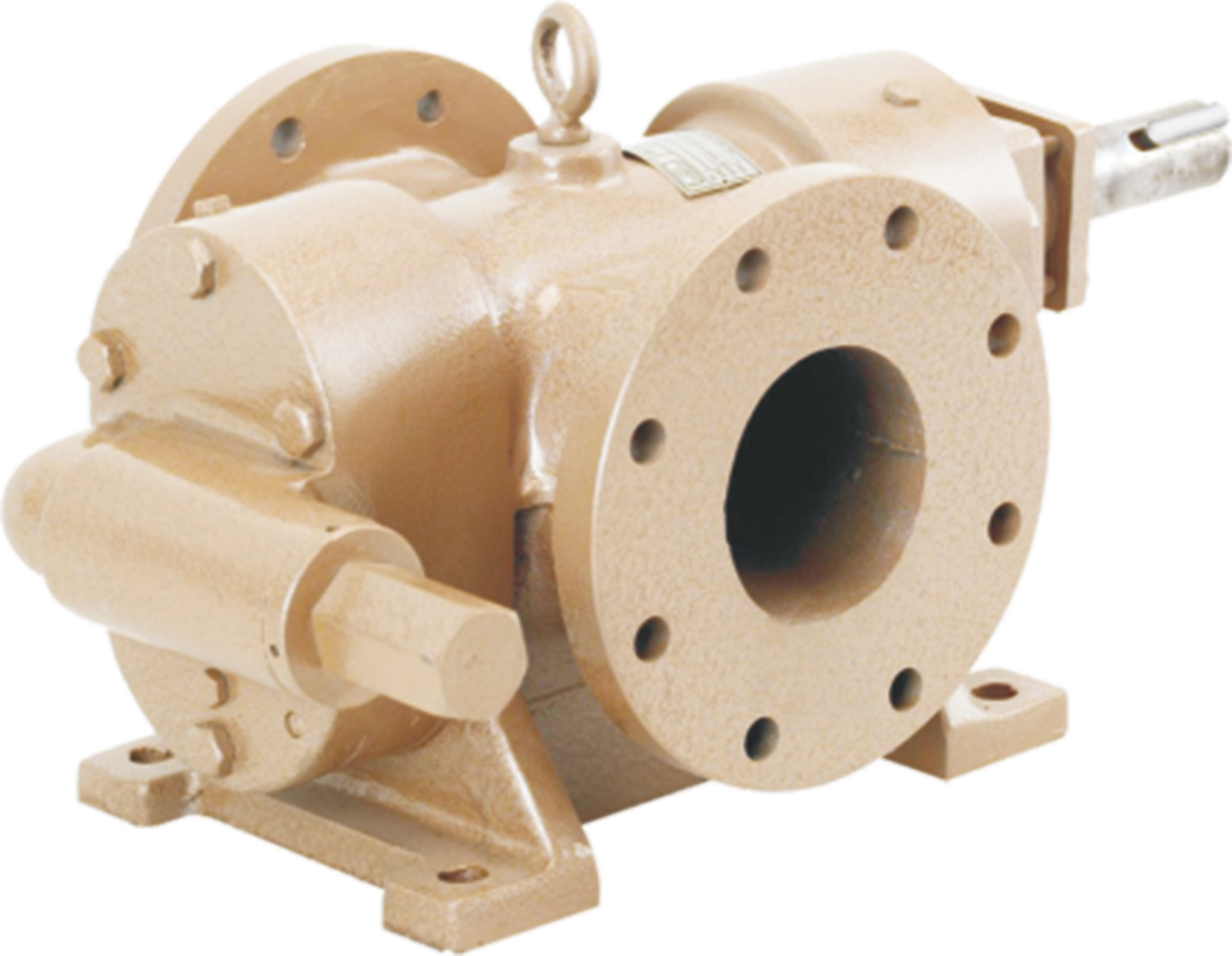

Provided by us is an optimum quality range of Rotary Gear Pumps to our esteemed patrons. We have a separate R&D team, which is involved in conducting research activities to produce an advanced range of pumps for the clients. The entire range of pumps is designed as well as made with the aid of our team of highly skilled professionals. Rotary Gear Pumps are widely appreciated in the market for their durability and excellent functioning.

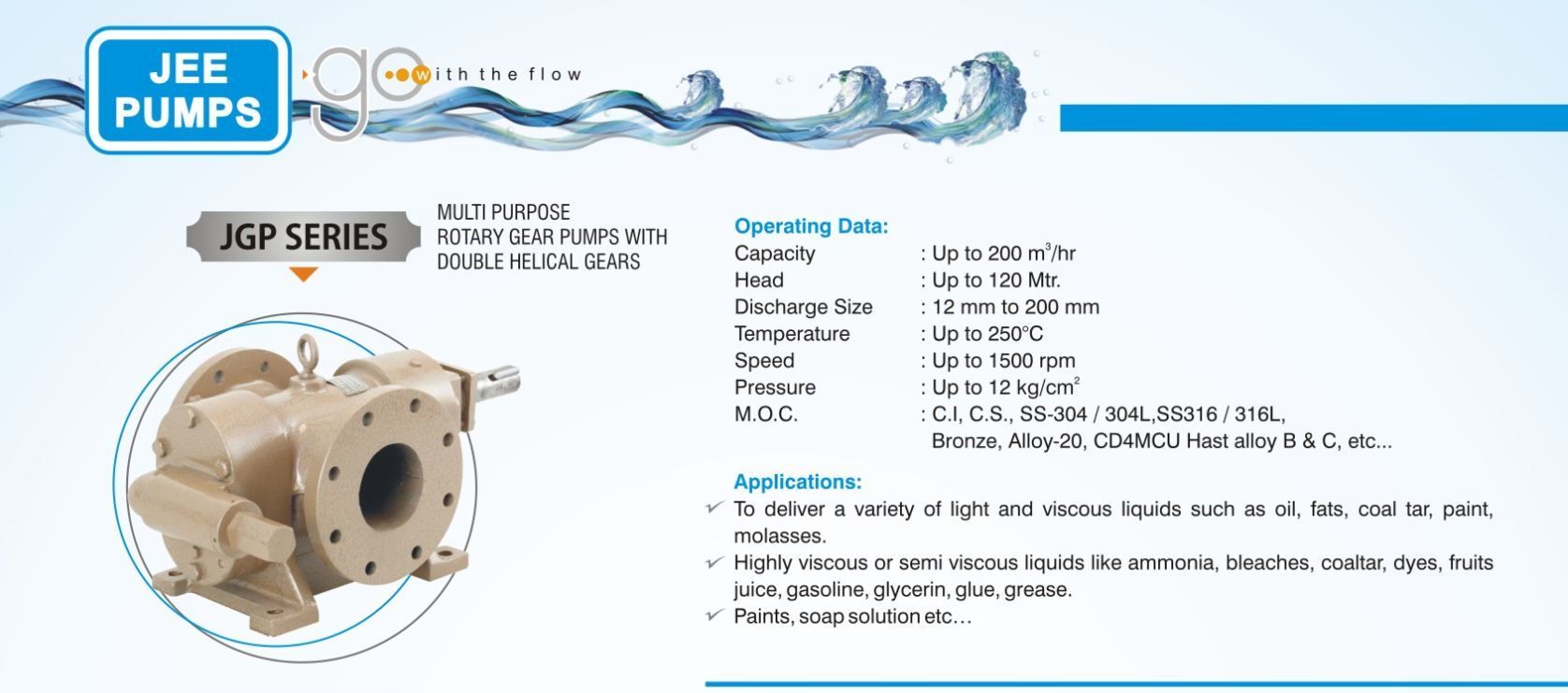

General Information :-

- JEE PUMPS series JGP pump are multi purpose rotary gear pumps with double helical gears are self priming pump with 5 mtr suction left compact in size

- Low noise high efficiency easy maintenance

- Longer life

- Economical

- Double helical gears to reduce axial thrust.

Applications :-

- L.D.O., Hot Grease And Tallow, F.O., Syrups, Glueplant, Thermic Fluid, Liquors, Milk, Bitumen, Resins And Pigments, Highly Viscouse Or Semi Viscouse Liquids, Soap Spary Mixturte, Soft Drinks, Tar , Glycerine, Food Industries, Kerosene, Dyes, Paper Pulp, Chemical Plants etc...

- To deliver a variety of light and viscous liquids such as coal tar, paint, molasses, oil, fats.

- Highly viscous or semi viscous liquids like ammonia, bleaches, gasoline, glycerin, glue, coaltar, dyes, fruits juice, grease, Paints, soap solution etc...

Operating Range :-

Technical Specification

Capacity - Q- Up To | 200 M3/Hr. |

TDH H - Up To | Up to 120 Mtr. |

Pump Sizes - DN | 12 mm To 200 mm |

Viscosity | 100000 CST |

Speed - N - | Max. Speed In 1440 rpm Reduction As A Function Of Viscosity |

Temperature | 250 C |

Pressure | Up to 12 kg/cm2 |

Material of Constructions :-

Cast Iron | Cast Steel ( WCB) |

Gun Metal | SS-304 |

SS-316 | Alloy- 20 |

Optional Accessories :-

- M.S. Fabricated Base Frame/Flexible Coupling/Coupling Guard/Foundation Bolt.

Efficient Fluid Transfer

Industrial Rotary Gear Pumps ensure consistent and reliable movement of oils, fuels, and chemicals. Their positive suction design enables seamless fluid handling, minimizing downtime and boosting operational efficiency in industrial settings.

Robust Build and Versatility

Manufactured from cast iron, stainless steel, or bronze, these pumps withstand harsh chemicals and demanding conditions. Offering multiple seal options and adhering to API and IS standards, they provide long-lasting performance for diverse industrial applications.

Flexible Installation and Quiet Operation

Engineered for base plate mounting, these pumps fit easily into existing setups and operate at a low noise level. The option for manual or automatic controls ensures adaptability and ease of use for different operational requirements.

FAQs of Industrial Rotary Gear Pumps:

Q: How does a rotary gear pump operate in industrial applications?

A: Rotary gear pumps utilize intermeshing gears to positively displace fluids such as oils, diesel, and chemicals, ensuring efficient and continuous transfer in industrial settings.Q: What materials are available for construction, and how do they benefit specific industries?

A: The pumps are constructed from cast iron, stainless steel, or bronze, providing durability and chemical resistance. This selection allows users to choose the optimal material for their particular fluid and operational environment.Q: Where can these pumps be installed and used within a facility?

A: These pumps are designed for base plate mounting, making them easy to install near storage tanks or process lines in chemical, petrochemical, pharmaceutical, or oil industry facilities.Q: When is it necessary to opt for a mechanical seal versus gland packing?

A: Mechanical seals are recommended for applications requiring minimal leakage and high reliability, while gland packing is suitable for less demanding cases, offering easier maintenance and lower initial cost.Q: What is the maximum suction and discharge pressure these pumps can handle?

A: They offer a maximum suction height of 5 meters and can deliver discharge pressures up to 10 Bar, making them suitable for various medium-pressure transfer tasks.Q: What benefits does low noise operation provide in an industrial environment?

A: Low noise pumps contribute to a safer and more comfortable working environment, reducing auditory fatigue and enabling easier compliance with occupational health regulations.Q: How does controlling the pump manually or automatically affect the process?

A: Manual control allows for operator oversight and customization, while automatic systems support streamlined large-scale operations, reducing labor and enhancing process consistency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM