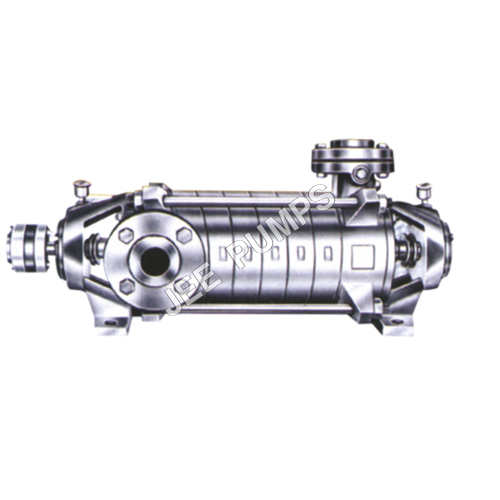

Cast Iron Multi Stage Centrifugal Pump

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 250 m/hr

- Material Cast Iron

- Structure Multi-Stage

- Suction Type Single or Double Suction

- Volute Type Single Volute

- Nozzle Location Top

- Click to View more

Cast Iron Multi Stage Centrifugal Pump Price And Quantity

- 01 Set

- 22000.00 INR/Set

Cast Iron Multi Stage Centrifugal Pump Product Specifications

- Horizontal

- Electric

- Designed for ambient water temperature

- Industrial, Irrigation, Water Supply, Boiler Feed

- Varies (typically 50mm to 150mm)

- Single Volute

- Up to 250 m/hr

- High Pressure Multi-Stage

- Multi-Stage

- Single or Double Suction

- Top

- Cast Iron

- Centrifugal Pump

- 1450/2900 rpm

- Non-Fuel (Electric Pump)

Cast Iron Multi Stage Centrifugal Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Cast Iron Multi Stage Centrifugal Pump

Promising quality in offered Cast Iron Multi Stage Centrifugal Pump is our quality manufacturing company. We employ modern technologies to produce pump of impressive performance. Superior quality materials such as cast iron, steel and bronze finds effective use in construction of our offered pump. We take high delight in rendering pump with zero clogging tendency. Excellent structural design allows the pump to operate in rigid working conditions. This highly assured quality of Cast Iron Multi Stage Centrifugal Pump do not produces high noise while operation and is extremely user-friendly. Pumping chemicals, ETP, STP & waste water treatment plants, steel and cement industries are some application areas of this product.

Features

- This pump comes with advanced features of zero air locking and vibration.

- Offered pump is widely appreciated for easily dealing with light slurries.

- The provided superior quality pump functions smoothly without sudden breakdowns.

- This pump requires minimal maintenance and is very simple in use.

Product Details:

| Capacity | Up to 453 m3/hr |

| Head | Up to 350 mtrs |

| Material of Construction | Cast Iron ,Bronze ,Steel |

| Temperature | -10 to +120 deg C |

| Speed | Up to 3500 RPM |

| Size | 32 mm to 50 mm |

| Pressure | Up to 35 kg / cm2 |

Rugged Industrial Construction

Constructed from high-quality cast iron, these centrifugal pumps are designed for longevity and consistent performance in rigorous industrial environments. The heavy-duty bearings, flexible coupling, and cast iron or bronze impeller handle both high pressure and flow demands with ease, ensuring uninterrupted operation in critical applications.

Versatile Mounting and Installation

With its foot-mounted configuration, the pump offers stability and simplified installation for both indoor and outdoor setups. Its anticorrosive coating and adaptable voltage range make it suitable for varied site requirements, while low noise operation keeps environments comfortable and safe.

Certifications and Quality Assurance

Manufactured to stringent standards and certified to ISO 9001:2015, this pump provides you confidence in compliance, quality, and reliability. The robust structure and long-life design contribute to reduced maintenance costs and higher operational efficiency.

FAQs of Cast Iron Multi Stage Centrifugal Pump:

Q: How is the Cast Iron Multi Stage Centrifugal Pump typically installed?

A: This pump is foot mounted for stable positioning and can be installed either indoors or outdoors, thanks to its anticorrosive coating and durable construction. It is designed for horizontal shaft orientation with easy connectivity to electric power sources.Q: What types of fluids and applications are suitable for this pump?

A: The pump is ideal for transferring ambient temperature water in industrial settings, irrigation, water supply systems, and boiler feed applications. Its multi-stage design and high pressure capacity support a flow rate up to 250 m/hr, suitable for demanding operations.Q: When should I choose a mechanical seal versus gland packing for this pump?

A: A mechanical seal is recommended for applications that demand superior leak prevention and minimal maintenance, while gland packing may be chosen for conditions where maintenance access is easier and initial cost savings are a priority.Q: Where can this pump be operated effectively?

A: This centrifugal pump is engineered for both indoor and outdoor operation, adapting to various environments due to its robust, anticorrosive build and flexible installation options.Q: What is the process for starting and maintaining the pump?

A: Ensure correct electrical connection (220V/380V/415V, 50 Hz/60 Hz), prime the pump, verify the bearings and seals, and gradually bring it to operational speed using the flexible coupling. Regular maintenance includes checking lubrication, inspecting seals, and monitoring bearing condition for optimal performance.Q: What are the main benefits of using this centrifugal pump?

A: Key benefits include high discharge head (up to 150m), efficient performance with low noise output, a long service life due to quality materials and engineering, and ISO 9001:2015 certification for assured reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM