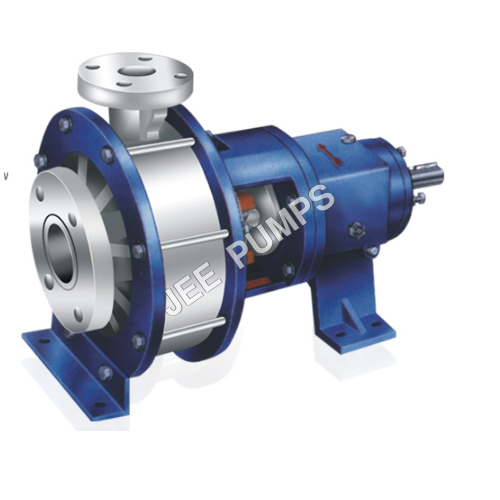

Industrial Closed Impeller Pump

Product Details:

- Theory Centrifugal Pump

- Inlet/Outlet 50 mm / 40 mm

- Frequency 50 Hz

- Speed 2900 RPM

- Max Suction 8 Meter

- Head Size 32 Meter

- Control System Manual

- Click to View more

Industrial Closed Impeller Pump Price And Quantity

- 1500 INR/Set

- 01 Set

Industrial Closed Impeller Pump Product Specifications

- 8 Meter

- Manual

- 32 Meter

- 2900 RPM

- 50 mm

- < 80 dB

- Horizontal

- Mechanical Seal

- Water Circulation, Irrigation, Industrial Process

- 50 Hz

- 50 mm / 40 mm

- Electric

- Centrifugal Pump

- 3.2 Bar

- Single Suction

- Self-Priming

- 220 V / 380 V

- Industrial

- Cast Iron / Stainless Steel

- Corrosion Resistant, High Efficiency, Sturdy Construction

- 3 HP

- Closed Impeller Pump

- -10C to 80C

- Max 3.2 Bar

- ISO 5199

- 30 m/h

- 30 m/h

- Single Stage

Industrial Closed Impeller Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Our offered Closed Impeller Pump is an ideal choice to be used for carrying volatile fluids due to the presence of close clearance wear rings. This pump works similar to the open impeller pump. The fluid enters through the impeller eye and then directed towards the discharge nozzle through energy generated by the vanes. However, the difference lies in the fact that it does not contain any impeller to volute. One of the best perks of buying the mentioned Closed Impeller Pump is its quality for which it is widely appreciated by not only our clients but users, as well.

Benefits

- Well known in the market for withstanding even the most challenging industrial conditions.

- The best pump to achieve precise results each time it is used.

- Never suffers any failures while functioning.

- Perfect buy to achieve excellence in sealing properties.

Specification

| Capacity | Up to 2200 m3/hr |

| Head | Up to 150 mtrs |

| Temperature | 350 Deg C |

| Speed | Up to 3500 rpm |

| Size | 25 mm to 300 mm |

| Pressure | Up to 15 kg/cm2 |

Corrosion-Resistant Construction

This pump is built with premium materialschoose from stainless steel or bronze for the impeller, paired with a cast iron or stainless steel body. Such construction resists corrosion, extending the pumps lifespan even in challenging industrial environments. These quality materials ensure reliable operation when handling various process liquids.

Highly Efficient & Reliable Operation

Engineered to achieve high efficiency, the pump operates at 2900 RPM while keeping noise levels below 80 dB. Its direct-coupled drive system, air-cooled design, and heavy-duty ball bearings contribute to stable, low-maintenance performance. The mechanical seal offers robust protection against leaks, making the pump suitable for continuous industrial use.

Versatile Industrial Applications

Conforming to ANSI/DIN flange standards and ISO 5199 specifications, this pump is adaptable for a wide range of uses, including water circulation, irrigation, and industrial processes. Its self-priming feature, single-stage structure, and sturdy construction make installation and operation straightforward for manufacturers, suppliers, and end users alike.

FAQs of Industrial Closed Impeller Pump:

Q: How is the Industrial Closed Impeller Pump typically used in industrial settings?

A: This pump is widely employed for water circulation, irrigation, and various industrial processes that demand robust and reliable fluid transfer. Its corrosion-resistant components make it adaptable to harsh environments and ensure long-term performance.Q: What benefits does the self-priming feature provide?

A: The self-priming capability allows the pump to evacuate air and begin operation automatically after initial filling, reducing startup hassles and minimizing maintenance compared to non-self-priming models.Q: When should I select stainless steel versus bronze impeller material?

A: Choose a stainless steel impeller for handling more corrosive or aggressive liquids. Bronze impellers are suitable for less corrosive environments, such as clean water or light industrial fluids, and may be preferred where lower cost is a priority.Q: Where can I install this pump and what are its mounting requirements?

A: This pump is designed for horizontal mounting and can be installed in industrial facilities, water treatment plants, or irrigation systems. Its compatibility with ANSI/DIN flange standards and ISO 5199 compliance ensures easy integration with existing systems.Q: What process steps are required for maintenance of the pump?

A: Routine maintenance includes checking the mechanical seal, inspecting bearings for wear, verifying alignment, and ensuring that the air cooling system is unobstructed. Regular monitoring maximizes pump efficiency and longevity.Q: How does the IP55 protection class benefit industrial operation?

A: IP55 ensures the pump is protected against dust ingress and low-pressure water jets from any direction, making it suitable for both indoor and outdoor industrial installations where exposure to harsh conditions might otherwise impact equipment reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free