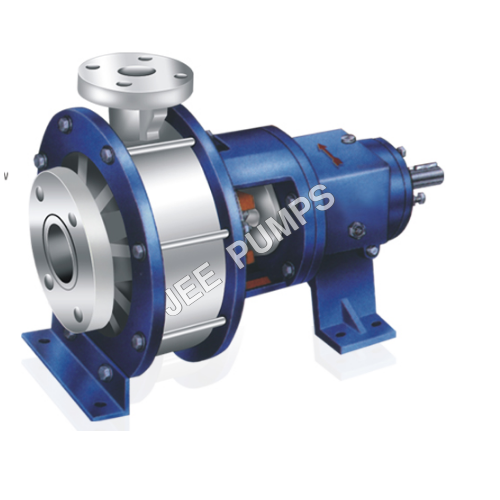

Industrial Acid Storage Tank Pump

Product Details:

- Inlet/Outlet 1 to 4 BSP/NPT

- Mounting Type Baseplate Mounted

- Control System Manual/Automatic (Optional)

- Theory Centrifugal Pump

- Frequency 50/60 Hz

- Caliber DN25 - DN100

- Noise Level <75 dB

- Click to View more

Industrial Acid Storage Tank Pump Price And Quantity

- 22000.00 INR/Set

- 01 Set

Industrial Acid Storage Tank Pump Product Specifications

- Acid Storage Tank, Chemical Process, Effluent Transfer

- 10-100 m/hr

- 0.5 HP to 10 HP

- Polypropylene (PP), PVDF, FRP, SS316

- N/A (Electric Driven)

- -10C to +80C

- 6-7 meters

- Corrosion Resistant, Maintenance Free, High Efficiency

- Up to 100 m/hr

- Max 3.5 kg/cm

- Up to 38 meters

- 220V / 380V

- Single-stage

- <75 dB

- 2900 RPM

- Industrial Acid and Chemical Transfer

- Electric

- DN25 - DN100

- Horizontal

- 50/60 Hz

- Self / Non Self Priming (Model Specific)

- Centrifugal Pump

- 3-4 bar (max)

- Manual/Automatic (Optional)

- Mechanical Seal / Gland Packing

- ISO 9001:2015

- Baseplate Mounted

- 1 to 4 BSP/NPT

- Horizontal Centrifugal

Industrial Acid Storage Tank Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

There is no denying to the fact that a wide variety of acids is widely used in all the sectors for different purposes such as making pharmaceutical products, household cleaning products and for industrial purposes, as well. However, the users have to be very careful while handling acids. For this reason, we bring into limelight Acid Storage Tank Pump that is made of high quality stainless steel and other material to ensure this pump remains in compliance with the industrial quality standards. Our offered Acid Storage Tank Pump is highly demanded in the market because of many reasons, of which some are cited below

- Components are made of unparalleled quality to carefully acid handling.

- Ensures high resistivity against the corrosion and rust.

- Innovative design that always attracts the customers.

- Known for its dimensional accuracy and efficient performance.

Specification

| Capacity | Up to 50 m3/hr |

| Head | Up to 45 mtr |

| Temperature | 80 deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 4.5 kg/cm2 |

| Discharge Size | 25 mm to 50 mm |

Superior Chemical Compatibility

Constructed from materials like polypropylene, PVDF, FRP, and stainless steel 316, this pump excels in transferring acids and chemicals with a minimum pH of 1. Its corrosion-resistant properties ensure reliability and long-term service even in harsh industrial conditions. This makes it ideal for applications where chemical resistance is critical.

Rugged, Efficient Operation

Delivering flow rates up to 100 m/hr and a head size of up to 38 meters, this horizontal centrifugal pump features self-priming or non-self-priming options depending on the model. Designed with an IP55 protection class and powerful electric motors (0.5 HP to 10 HP), it efficiently manages high-demand applications with a low noise output.

Flexible Installation & Maintenance-Free Design

The pump offers versatile installation thanks to both threaded and flanged connections, and can be baseplate mounted for stability. It supports easy set-up and integration into new or existing systems, and its maintenance-free design reduces operational interruptions, providing consistent performance over an extended service life.

FAQs of Industrial Acid Storage Tank Pump:

Q: How should the Industrial Acid Storage Tank Pump be installed?

A: The pump is designed for easy installation, with both threaded and flanged connection options to fit various system requirements. Baseplate mounting ensures stability, and the horizontal orientation makes integration straightforward in most industrial setups.Q: What types of chemicals and acids can this pump handle?

A: This pump is capable of transferring aggressive acids and chemicals with a minimum pH of 1 and viscosities up to 200 cP. Its construction from PP, PVDF, FRP, or SS316 ensures compatibility with a broad spectrum of corrosive substances commonly used in industrial processes.Q: When is it necessary to choose between a closed and a semi-open impeller?

A: A closed impeller is ideal for clean or slightly contaminated acids, providing high efficiency. A semi-open impeller is better suited for liquids containing solids or higher viscosities, offering greater tolerance to particulates and easier maintenance.Q: Where can this pump be utilized within industrial operations?

A: The pump is suitable for a variety of applications, including acid storage tanks, chemical processing plants, effluent transfer systems, and other industrial settings that require safe and efficient chemical movement.Q: What benefits does the corrosion-resistant material provide?

A: Constructed from high-grade corrosion-resistant materials, the pump ensures extended operational life, reduced maintenance, and minimized risk of leaks or degradation when exposed to harsh chemicals, saving both time and operational costs.Q: How is the operational safety and durability of the pump ensured?

A: With an IP55 protection rating, robust mechanical seal or gland packing options, and adherence to ISO 9001:2015 standards, the pump offers high durability and dependable performance in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM