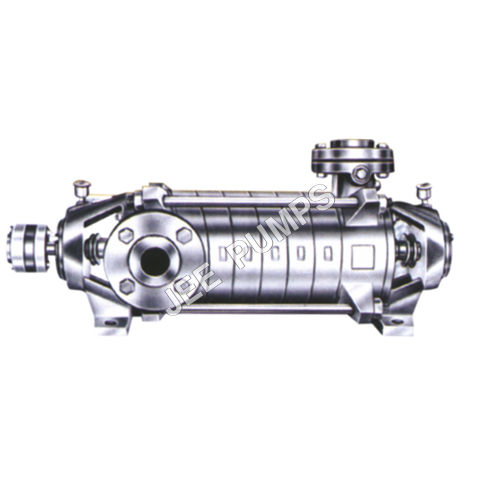

Industrial Boiler Feed Water Treatment Pump

23500.00 INR/Set

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 60 m/h

- Material Cast Iron & Stainless Steel

- Structure Horizontal Multistage

- Suction Type Single Suction

- Volute Type Double Volute

- Nozzle Location Top Discharge

- Click to View more

X

Industrial Boiler Feed Water Treatment Pump Price And Quantity

- 01 Set

- 23500.00 INR/Set

Industrial Boiler Feed Water Treatment Pump Product Specifications

- Up to 160C

- 2900 RPM

- Top Discharge

- Cast Iron & Stainless Steel

- Single Suction

- Up to 25 Bar

- Horizontal

- Boiler Feed, Industrial Water Treatment

- Double Volute

- Up to 60 m/h

- Horizontal Multistage

- Electric

- Centrifugal Pump

- None (Electric Operation)

- Inlet: 100 mm, Outlet: 80 mm

Industrial Boiler Feed Water Treatment Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Specifications:

| Capacity | Up To 150 m3/hr |

| Temperature | 120 Degree C |

| TDH Head | Up To 350 Mtr |

| Speed (at 60 Hz) | 1750 / 3500 rpm |

| Speed (at 50 Hz) | 1450 / 2900 rpm |

| Pump Sizes | DN 32 Mm To 100 Mm |

| Pressure | 38 Bars |

Robust Engineering for Industrial Demands

Built with a closed impeller and double volute structure, the pump is robustly constructed to handle boiler feed and water treatment operations. Cast iron and stainless steel materials ensure resistance to corrosion and longevity, while its horizontal multistage configuration delivers high pressure and consistent flow.

Efficient and Safe Operation

With motor insulation class F, IP55 protection, and air-cooled design, the pump is engineered for safety and efficiency. Its noise level remains below 85 dB, making it suitable for environments where minimal disturbance is essential. Automatic and manual controls accommodate diverse usage requirements.

Seamless Installation and Versatile Application

The base-mounted and horizontal shaft orientation makes installation straightforward. Compatible with various piping systems due to its inlet and outlet diameters, it serves critical functions in boiler feed and industrial water treatment across many sectors in India.

FAQs of Industrial Boiler Feed Water Treatment Pump:

Q: How does the pumps multi-stage centrifugal design benefit boiler feed applications?

A: The multi-stage centrifugal design enables the pump to generate higher pressures and maintains a steady flow, which is crucial for the reliable supply of treated water to boilers in industrial processes.Q: What materials are used in the construction of the pump, and how do they improve performance?

A: The pump is constructed from cast iron and stainless steel. These materials enhance durability, resist corrosion, and support continuous operation in harsh industrial environments.Q: When should manual or automatic controls be used with this pump?

A: Manual control is useful during maintenance or when adjustments are needed, while automatic control is ideal for continuous, efficient operation in automated environments.Q: Where is the ideal mounting position for installing this pump in an industrial facility?

A: The pump is designed for horizontal, base-mounted installation, typically placed near the boiler or within the water treatment system for optimal performance and easy access.Q: What is important about the pumps noise level during operation?

A: Operating below 85 dB, the pump minimizes workplace noise, making it suitable for locations where quiet operation is needed to protect worker health and meet industrial safety standards.Q: How is the pump protected for continuous operation under challenging industrial conditions?

A: The pump features IP55 motor protection and insulation class F, safeguarding it against dust, moisture, and overheating, thus ensuring reliable service in demanding environments.Q: What steps are involved in the process of commissioning this pump for boiler feed applications?

A: Commissioning includes installing the pump horizontally on a stable base, connecting appropriate inlet and outlet piping, configuring controls (manual or automatic), and verifying motor protection and cooling systems before regular operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Centrifugal Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free