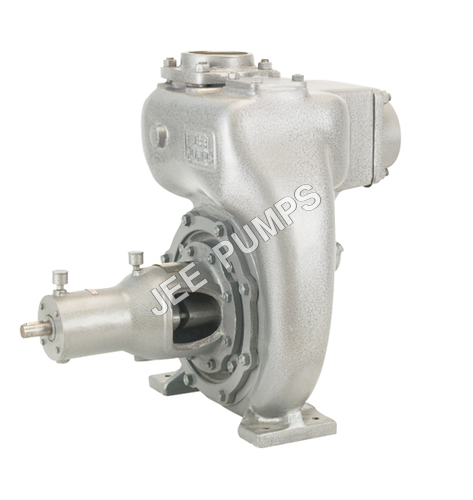

Industrial Centrifugal Mud Pump

Product Details:

- Flow Rate Up to 50 m/hr

- Theory Centrifugal Pump

- Material Cast Iron

- Structure Single Stage

- Suction Type Single Suction

- Volute Type Single Volute

- Nozzle Location End Suction

- Click to View more

Industrial Centrifugal Mud Pump Price And Quantity

- 01 Set

- 8500.00 INR/Set

Industrial Centrifugal Mud Pump Product Specifications

- Mud transfer, slurry handling, dewatering, construction sites

- Up to 8 bar

- Single Stage

- Single Volute

- Electric

- Horizontal

- Direct

- End Suction

- Up to 50 m/hr

- Cast Iron

- Up to 120C

- Single Suction

- Centrifugal Pump

- 2900 RPM

- Inlet: 100 mm, Outlet: 75 mm

Industrial Centrifugal Mud Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Centrifugal Mud Pump

Produced applying a modern technology is our Centrifugal Mud Pump that boasts of using centrifugal force for the transfer of fluids. This quality inspired pump is impressively designed to handle high viscosity drilling slurries. The sturdy design and powerful construction of the provided mud pump makes it appropriate for tough drilling conditions. Excellent stability and reduced vibration, enhances life of the pump. Our offered Centrifugal Mud Pump is highly acknowledged for being trouble-free in operation. The non-clogging feature allows in perfect dealing with suspended solids. The longer service life of our provided pump makes it a wonderful and beneficial purchase for clients.

Features

- Error-free functionality is the ruling attribute of our provided quality pump

- The provided pump is lighter in weight and excellent in speed

- Offered pump boasts of being very low on maintenance.

- This high quality pump is noted for being high energy efficient

Technical Specification

Discharge Size | 40 mm to 200 mm |

Power Source | Electric |

Pump Type | Centrifugal Pump |

Head | Up to 55 m |

Discharge Pressure | 5 Kg/cm2 (Maximum) |

Maximum Discharge Flow | 600 m3/hr. (Maximum) |

Temperature | 110 deg C |

Speed | Up to 3500 rpm |

Engineered for Rugged Performance

Our centrifugal mud pump is purpose-built to withstand harsh industrial, municipal, and mining environments. The cast iron construction and epoxy coating provide excellent durability against abrasion and corrosion. Its single-stage design facilitates easier maintenance and consistent performance. With direct electric drive and base mounting, installation is both straightforward and flexible for a variety of operational setups.

Optimized Handling of Solids and Slurries

Featuring a closed impeller and mechanical seal, this pump manages solids up to 15 mm efficiently. Its end suction, single volute configuration maximizes transfer rates, ensuring smooth and reliable handling of muddy fluids, slurries, and dewatering processes. The air-cooled motor ensures safety and longevity in extended operations without the need for water cooling.

FAQs of Industrial Centrifugal Mud Pump:

Q: How does the closed impeller design benefit mud and slurry transfer?

A: The closed impeller enhances efficiency by minimizing leakage and handling abrasive solids up to 15 mm. It maintains consistent flow and reduces wear, making it ideal for mud, slurry, and dewatering applications in industrial, municipal, or mining operations.Q: What are the main usage areas for this centrifugal mud pump?

A: The pump is commonly used in industrial, municipal, mining, and construction sites for mud transfer, slurry handling, and dewatering tasks. Its robust design ensures effective operation in environments demanding solid-laden fluid movement.Q: When should I choose a base-mounted, single-stage centrifugal pump?

A: Base-mounted, single-stage centrifugal pumps are preferable when users require stable installation, straightforward maintenance, and efficient operation for moderate pressure and flow rates. They are suitable for continuous-duty mud or slurry handling where reliability is paramount.Q: Where can this pump be sourced in India?

A: This pump is available via multiple supply channels in India, including distributors, exporters, manufacturers, suppliers, traders, and wholesalers. It can be ordered for industrial or commercial projects through authorized vendors.Q: What process steps are involved in installing this pump?

A: Installation involves securely fixing the base-mounted unit on a stable platform, connecting the inlet (100 mm) and outlet (75 mm) pipes, wiring the 415V AC, three-phase power supply, and ensuring IP55 protection compliance for safety. Final checks include verifying alignment, sealing, and cooling measures before operation.Q: How does mechanical sealing improve pump performance?

A: Mechanical seals minimize leakage and maintain pressure integrity, especially when handling abrasive and corrosive fluids. This enhances the pumps reliability, reduces maintenance frequency, and supports safer operation in continuous-duty environments.Q: What are the key benefits of using this mud pump for industrial applications?

A: Key benefits include efficient solid handling, quiet operation (below 70 dB), corrosion-resistant epoxy coating, high pump efficiency (up to 70%), motor protection (IP55), and adaptability for various heavy-duty uses such as dewatering, slurry transfer, and mud handling under temperatures up to 120C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free