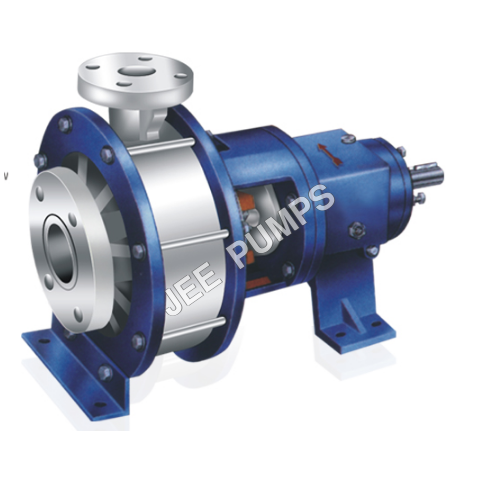

Industrial Glandless Pump

Product Details:

- Caliber Varies as per model

- Discharge Pressure Up to 5 kg/cm

- Frequency 50 Hz / 60 Hz

- Voltage 415 V / 230 V

- Control System Manual / Automatic Control

- Noise Level Low Noise Operation

- Flow Rate Up to 60 m/hr

- Click to View more

Industrial Glandless Pump Price And Quantity

- 01 Set

- 15400.00 INR/Set

Industrial Glandless Pump Product Specifications

- Industrial Liquid Transfer

- Up to 60 m/hr

- 50 Hz / 60 Hz

- Electric

- Up to 5 kg/cm

- Varies as per model

- Low Noise Operation

- Cast Iron / Stainless Steel

- Manual / Automatic Control

- 415 V / 230 V

- Up to 120C

- Up to 45 meters

- 2880 RPM or as per requirement

- Self Priming

- Up to 60 m/hr

- Centrifugal Pump

- Leak Proof, Maintenance Free, Compact Design, High Efficiency

- Glandless Pump

- ISI Standard

- Horizontal/Vertical Mount

- Chemical, Pharmaceutical, Food Processing, Water Treatment

- Up to 5 kg/cm

- 0.5 HP to 15 HP

- 25 mm x 25 mm to 100 mm x 100 mm

- Single Suction

- Mechanical Seal

- 5-6 meters

- Foot Mounted / Base Plate Mounted

Industrial Glandless Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Glandless Pump

The gland failure is one of the most common problem that is faced by many people who work in industrial sector, especially in chemical industry. To overcome this problem, we offer Glandless Pump that require no seal arrangement. Thus, eliminating all the chances of frequent maintenance and other associated issues like downtime. The offered pump is made of PP material so that our pump withstands even the corrosive liquids. Therefore, ensuring zero leakage. Glandless Pump is easy to install and uninstall whenever required. This pump can be used for phosphoric plants, caustic soda plant and gas washing plant.

Features

- This pump minimizes downtime for preventing the loss in production.

- Since the provided pump can even function with dry material, it does not require any seal or internal bearing.

- Prevents the failure of entire plant by resisting corrosion.

- Ensures low noise operations and higher production.

Specification

| Capacity | Up to 50 m3/hr |

| Head | 38 m |

| Max Flow Rate | 70 m3/h |

| Temperature | 80 Deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 4.5 kg/cm2 |

| Discharge Size | 25 mm to 50 mm |

Engineered for Industrial Durability

With options in AISI 410 or 304 stainless steel and cast iron construction, the Industrial Glandless Pump offers exceptional resistance to corrosion and wear. Its enclosed or semi-open impeller and heavy-duty sealed bearings ensure robust, trouble-free operationeven under high-pressure and high-flow conditions. The pumps compact, leak-proof design is tailored for industries requiring continuous, maintenance-free service.

Versatile Mounting & Flexible Connections

This glandless pump series supports both horizontal and vertical installations, making it adaptable to a wide variety of plant layouts. Connection types include both flanged and threaded options, matching standardized piping requirements. Whether foot mounted or base plate mounted, the pump integrates seamlessly with manual or automatic control systems, catering to diverse operational preferences.

Performance That Meets Stringent Standards

Operating at speeds up to 2880 RPM and managing flow rates up to 60 m/hr, this pump is engineered for efficiency and reliability. Certified to ISI standards, it handles a range of industrial fluids at temperatures up to 120C and pressures up to 5 kg/cm. The self-priming, single suction design optimizes both startup and continuous run, ensuring confidence in demanding environments.

FAQs of Industrial Glandless Pump:

Q: How does the glandless design benefit industrial applications?

A: The glandless design eliminates the risk of leakage associated with gland packing, resulting in leak-proof, maintenance-free operation. This is especially advantageous in hazardous or clean environments such as chemical, pharmaceutical, and food processing industries.Q: What is the recommended process for installing the Industrial Glandless Pump?

A: Installation is straightforward; the pump can be mounted horizontally or vertically, depending on your space requirements. It accepts both foot mounted and base plate mounting options and supports flanged or threaded connections for easy integration with existing piping systems.Q: When should I use an enclosed versus a semi-open impeller?

A: Enclosed impellers are ideal for handling clean or low-solid liquids, offering greater efficiency, while semi-open impellers are suitable for liquids containing suspended solids or slurries. Your choice depends on the nature of the fluid in your industrial process.Q: Where can this pump be utilized effectively?

A: This glandless pump is highly effective in industrial liquid transfer tasks found in chemical, pharmaceutical, food processing, and water treatment applications. Its robust construction and high efficiency also make it suitable for demanding environments where reliability is critical.Q: What are the primary usage benefits of this glandless pump?

A: Key benefits include leak-proof operation, minimal maintenance requirements, high efficiency, and reliable performance even at high temperatures and continuous duty cycles. Its compact design and flexible mounting further enhance operational convenience.Q: How is the pump protected from overheating and external elements?

A: The pump is equipped with an air-cooled motor, along with IP55-rated motor protection and insulation classes F or H, ensuring safe operation in ambient temperatures up to 50C and shielding against dust and water ingress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM