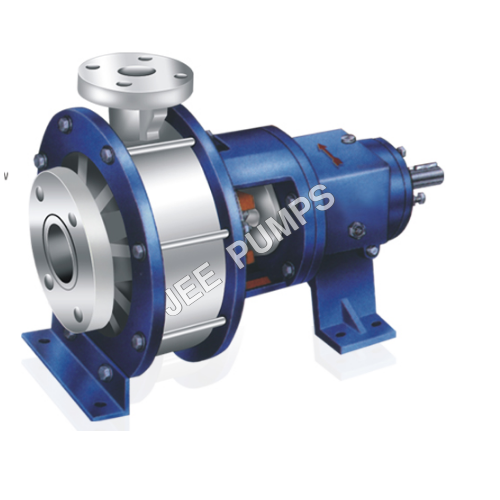

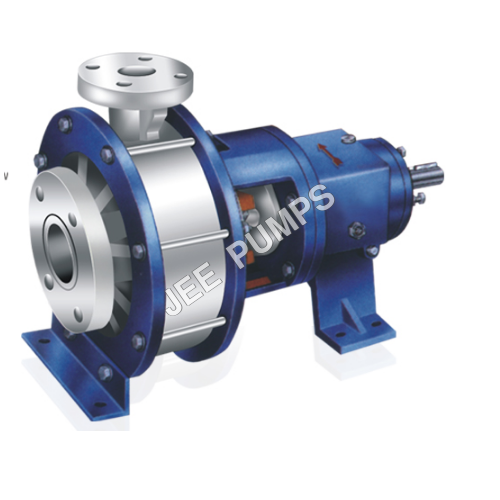

Industrial Polypropylene Pumps

Product Details:

- Working Temperature Up to 80C

- Speed 2880 RPM

- Discharge Pressure Up to 5 bar

- Head Size Up to 28 meters

- Mounting Type Baseplate Mounted

- Voltage 220-240V

- Flow Rate Up to 20 m/hr

- Click to View more

Industrial Polypropylene Pumps Price And Quantity

- 22000.00 INR/Set

- 01 Set

Industrial Polypropylene Pumps Product Specifications

- Corrosion resistant, leak proof, low maintenance

- Up to 5 bar

- ISO 9001:2015

- Industrial Chemical Transfer

- Self Priming / Non Self Priming Available

- 25 mm x 25 mm to 75 mm x 75 mm

- 50 Hz

- Direct Suction

- Up to 3.5 meters

- 70 dB

- Manual

- Centrifugal Pump

- Centrifugal Chemical Pump

- Single-stage

- Mechanical Seal

- 1 HP to 5 HP

- Baseplate Mounted

- 2880 RPM

- Up to 5 bar

- Up to 28 meters

- Polypropylene

- Up to 20 m/hr

- Up to 80C

- Electric

- 25 mm to 75 mm

- Up to 20 m/hr

- 220-240V

- Acids, Alkalis, Chemicals & Effluent Handling

Industrial Polypropylene Pumps Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Our top grade Polypropylene Pumps are trusted by many experts of chemical as well as water treatment industries. Such group of experts rely on our pumps completely due to the reliable designs, operational efficiency and service life of our pumps. The robust build, impact tolerant bodies and impressive corrosion resistance of our quality assured Polypropylene Pumps contributes regularly to the massive popularity of our pumps. These pumps are used with trust in chemical processing, plating as well as water treatment applications. Our pumps are also acclaimed in the market for having practical designs, reliable sizes and maintenance free service life.

Features:

- Our pumps have absolutely zero operational, mechanical and physical defects

- Our pumps are engineered in perfect compliance to international standards

- Our pumps are quality tested prior to sale

- Our pumps are made available in varied sizes, designs and dimensional specifications

Specifications:

|

Capacity |

Up to 50 m3/hr |

|

Head |

Up to 45 mtr |

|

Temperature |

80 deg C |

|

Speed |

Up to 3500 rpm |

|

Pressure |

Up to 4.5 kg/cm2 |

|

Discharge Size |

25 mm to 50 mm |

Durable and Corrosion-Resistant Design

Crafted from high-quality polypropylene and coated with anti-corrosive paint, these pumps are resilient against harsh chemicals and industrial environments. The SS 316 shaft and thoughtful seal materials ensure longevity, leak-proof performance, and reliable handling of aggressive media. Their robust build makes them perfect for continuous operation in chemical processing and wastewater applications.

Versatile Application and Configuration

Choose between closed or semi-open impellers, self-priming or non-self-priming versions, and various inlet/outlet sizes (25 mm to 75 mm). Compatible with both flanged and threaded connections, these pumps deliver flexible installation in diverse plant settings. They handle solids up to 6 mm, operate up to 80C, and manage suction up to 3.5 meters, covering a wide scope of industrial transfer needs.

FAQs of Industrial Polypropylene Pumps:

Q: How is the polypropylene pump installed and operated for chemical transfer applications?

A: Install the pump on a stable baseplate using the provided flanged or threaded connections for inlet and outlet. Connect the pump to a 220240V power supply, and ensure all seals are intact. Operation is manual via the control system, making it straightforward for industrial chemical transfer tasks.Q: What substances and industries can this pump handle effectively?

A: The pump is designed for handling acids, alkalis, chemicals, and effluents in industrial settings. It is suitable for industries such as chemical processing, wastewater treatment, pharmaceuticals, and any application requiring robust chemical transfer solutions.Q: When should I choose a self-priming vs non-self-priming version?

A: Opt for the self-priming version when the pump needs to lift liquids from a level below the installation point or start without manual priming. Non-self-priming is suitable when gravity feed is available or manual priming is feasible.Q: Where can these pumps be deployed within an industrial facility?

A: These pumps can be installed wherever chemical or effluent transfer is required, such as process lines, storage tank transfers, and effluent treatment plants. Their versatility and corrosion resistance allow them to function in both indoor and outdoor industrial environments.Q: What is the process for maintaining and servicing the pump?

A: Maintenance is minimal due to the corrosion-resistant materials and leak-proof design. Regularly inspect seals, check for debris that may exceed the 6 mm solid passage, and ensure electrical connections are secure. Periodic cleaning ensures optimal performance and longevity.Q: What are the benefits of using this centrifugal polypropylene pump compared to metal pumps?

A: Polypropylene pumps offer exceptional chemical resistance, lighter weight, and reduced risk of corrosion compared to metal pumps. This results in lower maintenance needs, longer service life in harsh chemical environments, and overall cost-effectiveness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM