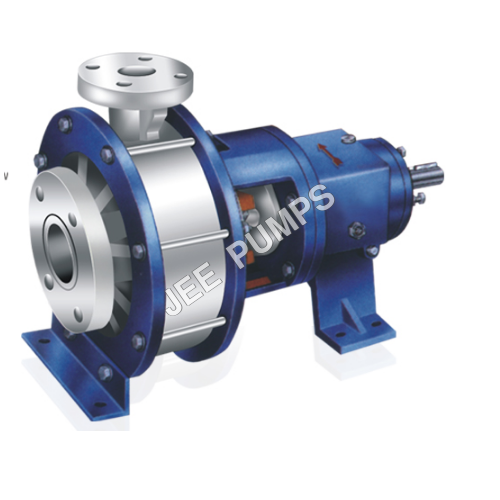

Jppl Series Corrosion Resistant Polypropylene Pumps

35200 INR/Piece

Product Details:

- Caliber Varies by Model (25 mm - 100 mm)

- Noise Level Low Noise Operation (< 75 dB)

- Discharge Pressure Up to 4.2 kg/cm

- Features Non-Metallic Construction, Highly Corrosion Resistant, Easy Maintenance

- Inlet/Outlet 25 mm x 25 mm to 100 mm x 100 mm

- Working Temperature Up to 80C

- Control System Manual / Automatic (Optional)

- Click to View more

X

Jppl Series Corrosion Resistant Polypropylene Pumps Price And Quantity

- 1 , , Piece

- 35200 INR/Piece

Jppl Series Corrosion Resistant Polypropylene Pumps Product Specifications

- Corrosion Resistant Polypropylene Pump

- ISI Standard Compliance

- Up to 3.5 Mtr

- Single-Stage Centrifugal

- Centrifugal Pump

- Up to 4.2 kg/cm

- Base Plate / Foot Mounted

- Up to 42 mtr

- Up to 105 m/hr

- Polypropylene (PP), Corrosion Resistant

- 220-240 V

- Flooded/Self Priming (Model Dependent)

- Electric Driven

- Up to 80C

- Non-Metallic Construction, Highly Corrosion Resistant, Easy Maintenance

- 25 mm x 25 mm to 100 mm x 100 mm

- Low Noise Operation (< 75 dB)

- Up to 4.2 kg/cm

- Varies by Model (25 mm - 100 mm)

- 2900 RPM

- 50 Hz

- Mechanical Seal (Viton/EPDM Envelope)

- Chemical Industry, Effluent Treatment, Electroplating, Pharmaceuticals

- Self-priming (available for select models)

- Manual / Automatic (Optional)

- Chemical Transfer, Acid Handling, Waste Water, Effluent

- 0.5 HP to 15 HP

- Up to 105 m/hr

Jppl Series Corrosion Resistant Polypropylene Pumps Trade Information

- 1 , , Piece Per Day

- 1 Days

Product Description

Specification

| Capacity | Up to 300 m3/hr |

| Discharge Size | 50 mm to 100 mm |

| Material Of Construction | PP,UHMWPE |

| Pressure | Up to 6.5 kg/cm2 |

| Speed | Up to 3500 rpm |

| Temperature | Up to 80 Deg C |

| Head | Up to 65 mtr |

Industrial-Grade Corrosion Resistance

Constructed from premium molded polypropylene, Jppl Series pumps are engineered to withstand corrosive chemicals and demanding industrial fluids. The non-metallic design is ideal for handling acids, alkaline solutions, and harsh wastewater, offering dependable resistance to chemical attack, corrosion, and physical wear in a wide range of environments.

Robust Performance Features

Featuring a centrifugal design with heavy-duty ball bearings and impeller options (closed or semi-open), these pumps provide efficient solid handling up to 5 mm and can deliver high flow rates up to 105 m/hr. The IP55 protection class ensures secure operation, while the base plate or foot mounting adds installation flexibility.

Versatile and Easy Maintenance

Available in multiple configurations, the Jppl Series pumps accommodate various process requirements, from chemical transfer to effluent management. Mechanical seals in Viton or EPDM guarantee leak-proof operation, while user-friendly design allows for straightforward maintenance, minimizing downtime for industrial operations.

FAQs of Jppl Series Corrosion Resistant Polypropylene Pumps:

Q: How are Jppl Series Corrosion Resistant Polypropylene Pumps installed and operated?

A: Jppl Series pumps are base plate or foot mounted for secure installation and connect via flanged inlets/outlets. They operate on electric power (220-240 V, 50 Hz) and can be run manually or with optional automatic controls. Always ensure correct direction of rotation (clockwise when viewed from the drive end) for optimal operation.Q: What makes these pumps suitable for handling aggressive chemicals and corrosive fluids?

A: Their non-metallic polypropylene construction offers exceptional corrosion resistance against acids, alkalis, and industrial effluents, making them highly suitable for chemical transfer, electroplating, and wastewater applications. The mechanical seals (Viton/EPDM) further prevent leaks and chemical ingress.Q: Where can Jppl Series pumps be effectively utilized?

A: These pumps are widely used in the chemical industry, effluent treatment plants, electroplating facilities, and the pharmaceutical sector across India and international markets. Their durability and corrosion resistance make them ideal for various aggressive liquid transfer needs.Q: What processes can benefit from using these corrosion resistant pumps?

A: Processes involving the transfer of acids, alkalis, waste water, or other corrosive fluids will benefit significantly due to the pumps high chemical resistance and reliable solid handling up to 5 mm, along with ISI standard compliance.Q: When should self-priming or flooded suction models be considered?

A: Self-priming models are recommended when installation positions the pump above the liquid level (maximum suction up to 3.5 meters), simplifying start-up and reducing manual intervention. For applications where the liquid source is above the pump inlet, flooded suction models are adequate.Q: How easy is maintenance for the Jppl Series pumps, and what features support this?

A: Designed for easy maintenance, the pumps feature accessible mechanical seals and heavy-duty bearings. The modular structure allows quick disassembly for part replacement or cleaning, minimizing downtime during routine servicing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Polypropylene Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free