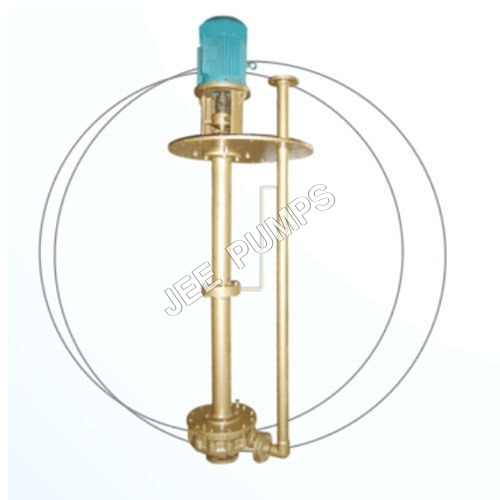

Industrial Acid Transfer Pump

Product Details:

- Inlet/Outlet 1 inch / 1 inch

- Voltage 220V / 380V

- Caliber 25 mm

- Speed 2900 RPM

- Head Size 20 meters

- Control System Manual

- Frequency 50 Hz

- Click to View more

Industrial Acid Transfer Pump Price And Quantity

- 1 Set

Industrial Acid Transfer Pump Product Specifications

- 2.0 bar

- Single Stage

- Polypropylene, SS316

- Below 70 dB

- Electric

- ISO 9001:2015

- Chemical, Acid, Pharmaceutical, Water Treatment

- Self Priming

- Centrifugal Pump

- Corrosion Resistant, Leak Proof, Easy Maintenance

- 60 LPM

- Acid Transfer Pump

- 4 meters

- 0.5 HP to 2 HP

- Base Mounted

- Industrial Acid Transfer

- 0C to 80C

- 1 inch / 1 inch

- Positive Displacement

- 220V / 380V

- Mechanical Seal

- 25 mm

- 2.0 bar

- 20 meters

- 2900 RPM

- 3600 LPH

- Manual

- 50 Hz

Industrial Acid Transfer Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Our top grade Acid Transfer Pumps are acclaimed for having a reliable service life, they function for a long period of time without any glitch. The pumps are highly resistant to corrosive chemicals and hazardous acids. This helps many in the acid industry to transfer such hard to manage substances from one place to another. The Acid Transfer Pumps that we offer are completely leak proof. They can be trusted fully as they have the support of a huge expert group. One can rely on the impact tolerant and abrasion resistant bodies of our transfer pumps, they are quality tested prior to sale.

Features

- Our pumps are priced in a reasonable manner.

- Our pumps have no operational issues and require close to zero maintenance

- Our pumps can last without repair for a long period of time

- Our pumps have a powerful engine

Specification

|

Length |

Up to 4 mtrs |

|

Motor Horsepower |

20 - 140 HP |

|

Head |

15 to 50 m |

|

Motor Phase |

Three Phase |

|

Brand |

Jee pumps |

|

Number Of Stages |

Single-stage Pump |

|

Capacity |

Up to 350 m3/hr |

|

Model Number/Name |

JVSP |

|

Temperature |

Up to 160 deg C |

|

Speed |

Up to 3500 RPM |

|

Pressure |

Up to 10 kg / cm2 |

Efficient Acid Handling Technology

Equipped with a closed impeller and self-priming feature, this pump is engineered for smooth acid transfer with minimized leakage risks. The robust SS316 shaft and polypropylene construction ensure outstanding chemical resistance and longevity. Consistent performance is achieved even under varying density and viscosity, supporting a range of industrial workflows.

Versatile Industrial Applications

The durable single-stage centrifugal pump is compatible with both single and three-phase power supplies and operates efficiently at 50 Hz and 220V/380V. It serves various industries, including chemical manufacturing, pharmaceuticals, and water treatment, providing reliable liquid handling and safe operation around the clock.

Easy Operation and Maintenance

Designed for user-friendly installation and upkeep, the pump features a base-mounted structure and manual controls. Its mechanical seals prevent leaks, and the 2-meter cable ensures flexible positioning. Routine maintenance is straightforward, minimizing downtime and ensuring continuous, efficient workflow.

FAQs of Industrial Acid Transfer Pump:

Q: How do I install the industrial acid transfer pump for optimal performance?

A: Install the pump on a stable, level base near the acid storage tank. Ensure the inlet and outlet are correctly connected (both 1 inch), and use the 2-meter cable to connect to a single or three-phase power supply (220V/380V). Priming is self-automated, and positive displacement suction makes set-up straightforward.Q: What types of liquids can this pump safely transfer?

A: This pump is suitable for acids, chemicals, and water-based solutions with a maximum liquid density of 1.9 g/cm and viscosity up to 100 cP. Its corrosion-resistant materials, SS316 and polypropylene, allow safe handling of a wide range of aggressive and corrosive substances.Q: When is periodic maintenance required for the pump?

A: Its recommended to perform routine maintenance every three to six months, depending on usage intensity. Regular checks should focus on seal integrity, impeller cleaning, and ensuring the motor protection (IP55) remains effective to prevent ingress of dust and water.Q: Where can this acid transfer pump be used most effectively?

A: The pump is ideal for chemical plants, pharmaceutical factories, water treatment facilities, and any application requiring fast, consistent acid or chemical transfer. Its compact, base-mounted design allows flexible placement within diverse industrial settings.Q: What is the process for replacing the mechanical seal on this pump?

A: First, disconnect the pump from the power supply and remove it from service. Detach the casing to access the mechanical seal. Carefully remove the old seal and replace it with a compatible seal (as specified in the manual), then reassemble and test for leaks before resuming operation.Q: How does this pump benefit industrial acid transfer operations?

A: It offers leak-proof and corrosion-resistant performance, handles high-density liquids, and is certified to ISO 9001:2015 standards. With easy installation, low maintenance, and a noise level below 70 dB, it ensures safe, efficient, and sustainable operations for challenging industrial environments.Q: What are the key features that ensure safety and reliability during pump usage?

A: The pumps motor (IP55) is protected against dust and splashes, while mechanical seals and SS316 shaft material prevent leaks even with aggressive fluids. Its manual control system allows careful operation, and the design accommodates particles up to 2 mm, reducing clogging risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free