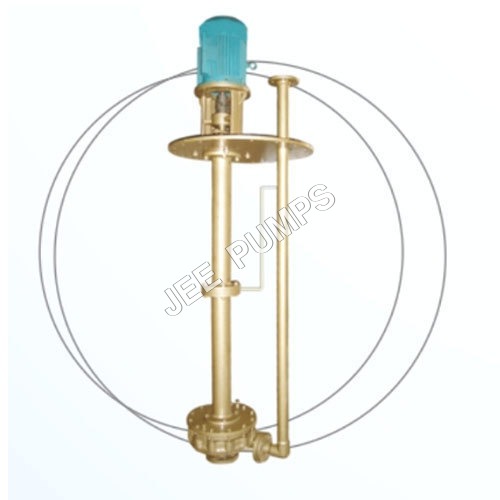

Industrial Vertical Acid Transfer Pump

Product Details:

- Head Size 6-40 m

- Discharge Pressure 3-5 Bar

- Speed 2800 RPM

- Caliber 32 mm, 40 mm, 50 mm

- Flow Rate 3-45 m/h

- Max Suction 6 m

- Noise Level <75 dB(A)

- Click to View more

Industrial Vertical Acid Transfer Pump Price And Quantity

- 1 Set

Industrial Vertical Acid Transfer Pump Product Specifications

- ISO 9001:2015

- 0.75 kW to 7.5 kW

- Immersible / Vertical Acid Transfer Pump

- Vertical Flange Mount

- -10C to 85C

- NA (Electric Driven)

- Corrosion Resistant, Heavy Duty, Anti-leakage, Maintenance Free

- Manual / Electric Panel

- 40 mm / 32 mm

- Chemical, Acid, Wastewater, Electroplating, Textile

- Up to 5 Bar

- 6 m

- Centrifugal Pump

- <75 dB(A)

- 50/60 Hz

- 220-380 V

- As per requirement

- Single Stage Vertical

- Electric

- 3-45 m/h

- 32 mm, 40 mm, 50 mm

- 6-40 m

- Polypropylene / FRP / SS 316 Volute

- 2800 RPM

- Mechanical Seal

- Vertical Suction

- 3-5 Bar

- Self-priming not required (vertical design)

- Industrial Acid Transfer

Industrial Vertical Acid Transfer Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Our top grade Vertical Acid Transfer Pumps are completely leakage proof, they are magnetic drive pumps that rotates with the support of magnetic drive instead of impellers or shaft seal. These pumps are also renowned for their mechanical efficiency, which is backed with zero slippage guarantee. Our quality tested Vertical Acid Transfer Pumps are reliable, they function without any glitch in the long run. Their seamless finish and design accuracy attracts a huge customer base in the marketplace. The acid transfer pumps can handle extreme temperatures without sustaining any major damages. One can rely on these quality tested transfer pumps that we offer.

Features

- Our pumps have impact tolerant, acid proof and corrosion resistant bodies

- Our pumps are designed to fit the diverse needs of clients in a wide variety of sizes

- Our pumps are highly durable and require minimal maintenance

- Our pumps showcase an efficient performance throughout the entirety of operational life

Specification

|

Length |

Up to 4 mtrs |

|

Motor Horsepower |

20 - 140 HP |

|

Head |

15 to 50 m |

|

Motor Phase |

Three Phase |

|

Brand |

Jee pumps |

|

Number Of Stages |

Single-stage Pump |

|

Capacity |

Up to 350 m3/hr |

|

Model Number/Name |

JVSP |

|

Temperature |

Up to 160 deg C |

|

Speed |

Up to 3500 RPM |

|

Pressure |

Up to 10 kg / cm2 |

Reliable Corrosion Resistance

Engineered from advanced materials such as Polypropylene, FRP, and SS 316, each pump features a robust anti-corrosive body finish, ensuring long-lasting resistance to acidic and chemically aggressive fluids. This construction significantly extends the service life while keeping maintenance minimal even under the most demanding industrial conditions.

Efficient Continuous Operation

With heavy-duty sealed bearings, an automatic or manual operation mode, and the ability to run at 2800 RPM, this pump is purpose-built for continuous duty cycles in challenging environments. Its high flow rate (345 m/h) and vertical suction design ensure smooth, uninterrupted transfer of acids and chemicals.

Versatile Industrial Applications

Supporting a broad spectrum of industries, including chemical, wastewater, electroplating, textile, and more, this pump meets a wide range of transfer and circulation needs. Its compliance with ISO 9001:2015 standards and a wide voltage range makes it adaptable and dependable for both standard and specialized industrial setups.

FAQs of Industrial Vertical Acid Transfer Pump:

Q: How does the vertical acid transfer pump operate in continuous industrial processes?

A: This pump is designed for continuous operation using a centrifugal pumping theory and heavy-duty sealed bearings. It can be installed with automatic or manual control, making it ideal for non-stop fluid transfer in manufacturing, processing plants, and chemical handling environments.Q: What are the benefits of choosing a pump with a semi-open or closed impeller design?

A: Semi-open impellers facilitate the handling of solids and viscous acids, while closed impellers improve efficiency and are ideal for transferring cleaner fluids. The dual option allows end-users to select the optimal impeller type based on their specific application.Q: When is the ideal installation depth for this vertical pump?

A: The recommended installation depth is between 0.5 to 2 meters, ensuring stable operation and preventing air entrainment. This flexibility allows the pump to be tailored to various tank configurations and operational needs.Q: Where can this acid transfer pump be applied?

A: It is widely used in chemical plants, acid storage and transfer stations, electroplating facilities, textile processing, and wastewater treatment plants, owing to its robust corrosion resistance and ability to handle aggressive fluids.Q: What is the typical process for starting and operating the pump?

A: The pump can be started using either the manual switch or an electric control panel, depending on the installed option. No priming is required due to the vertical design. Regular monitoring ensures optimal flow and head levels tailored to the application.Q: How does the anti-corrosive coating enhance the pumps durability?

A: The anti-corrosive coating, combined with materials such as Polypropylene, FRP, or SS 316, guards against chemical attack and abrasion, extending the pumps operational lifespan even in harsh acid transfer conditions.Q: What usage and operational benefits does this pump offer for industrial environments?

A: This pump offers maintenance-free performance, high efficiency, and minimal leakage risk. Its robust construction, noise level below 75 dB(A), and compliance with ISO standards make it an optimal choice for demanding industrial acid and chemical transfer applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM