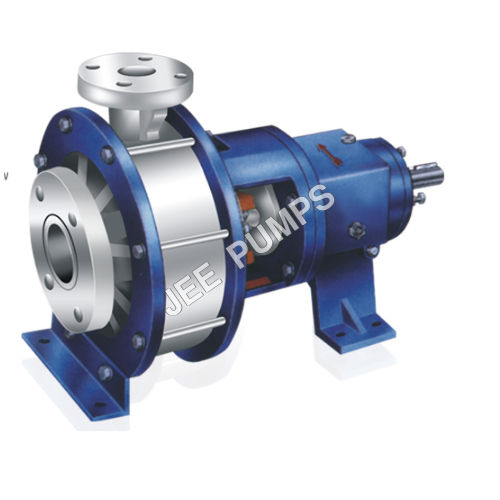

Industrial PP Pump

Product Details:

- Theory Centrifugal Pump

- Working Temperature Up to 80C

- Mounting Type Base Mounted

- Noise Level Below 65 dB

- Flow Rate Up to 110 m/hr

- Caliber 25 mm - 75 mm

- Frequency 50/60 Hz

- Click to View more

Industrial PP Pump Price And Quantity

- 01 Set

- 22000.00 INR/Set

Industrial PP Pump Product Specifications

- Up to 3 meters

- 0.5 HP to 10 HP

- Flooded Suction/Negative Suction

- Manual/Optional Auto Control

- Corrosion & Chemical Resistant, Leak Proof, Easy Maintenance

- 3.6 bar (max)

- 50/60 Hz

- 25 mm - 75 mm

- 220-415V

- PP Chemical Process Pump

- 2800 RPM

- Electric

- Maximum 3.6 bar

- Polypropylene (PP)

- Up to 36 meters

- 25 mm x 25 mm - 75 mm x 75 mm

- Self-Priming (Optional)

- Below 65 dB

- Up to 110 m/hr

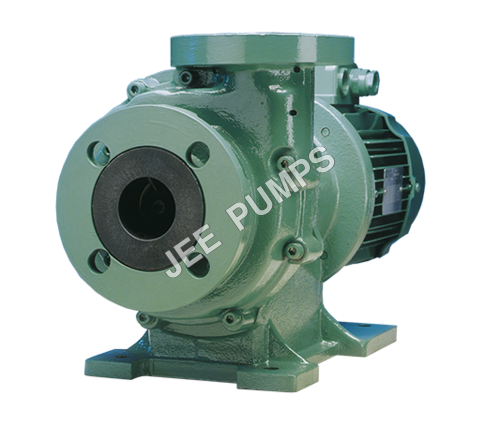

- Single-stage Horizontal

- Up to 110 m/hr

- Centrifugal Pump

- Acid/Alkali Handling, Chemical Process, Effluent Treatment

- Industrial Chemical Transfer

- Mechanical Seal

- Up to 80C

- Base Mounted

- ISO 2858 / DIN

Industrial PP Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

We offer Poly Propylene Pumps that occupy minimum space and ensures maximum performance. This makes it worth appreciating in many industries, especially in the chemical industry for fertilizers plants, thermal plants and atomic power plants. All the components used in the making of our pump are carefully engineered using solid injection molding process. While manufacturing this pump, top grade poly propylene material is used for conveying considerable inertness against the chemicals. The use of this material also prevents our Poly Propylene Pumps from the damage that may be caused by corrosive chemicals. Hence, ensuring longevity of the pump for a long time period.

Features

- Simple operations that do not cause any noise.

- Ideal to be used for Phosphoric Acid Plants, Rayon Plants and Gas Washing Plants.

- Fitted with PTFE bellow mechanical seal or regular seal, as per the requirements of our clients.

- Offers vibration free, leakage free and noise free operations.

Specification

| Capacity | Up to 50 m3/hr |

| Head | Up to 45 mtr |

| Temperature | 80 deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 4.5 kg/cm2 |

| Discharge Size | 25 mm to 50 mm |

Versatile and Reliable Chemical Transfer Solution

This highly durable PP pump is designed for the safe and effective transfer of various aggressive chemicals, including acids, alkalis, and solvents. Engineered for industrial standards such as ISO 2858 and DIN, this pump excels in demanding applications like chemical processing and effluent treatment. The corrosion-resistant design, leak-proof mechanical seals, and flexible mounting options make maintenance easy and ensure reliable long-term performance.

Engineered to Withstand Tough Operating Conditions

Equipped with heavy-duty ball bearings and an IP55 protection class, this pump operates dependably even in challenging environments. It supports voltages from 220V to 415V, offers flow rates up to 110 m/hr, and manages heads up to 36 meters. Its robust structure is engineered to be leak-proof and maintain a low noise levelbelow 65 dBproviding peace of mind for operators.

FAQs of Industrial PP Pump:

Q: How does the closed or semi-open impeller type benefit chemical handling in this PP pump?

A: The use of closed or semi-open impellers enhances the pumps ability to handle a range of fluids with varying viscosities and solid content. This design allows for reliable performance and reduced clogging, particularly important for industrial chemical and effluent processing.Q: What liquids are suitable for transfer using this industrial PP pump?

A: This pump is engineered for compatibility with corrosive and chemically aggressive liquids such as acids, alkalis, and solvents. Its polypropylene construction and mechanical seal provide strong resistance against chemical attack, making it ideal for industrial applications.Q: Where can the PP chemical process pump be installed for maximum efficiency?

A: For optimal operation, install the pump in an environment that meets its mounting and suction requirements, such as in process plants, effluent treatment facilities, or chemical handling stations. The base-mounted structure ensures stable performance, and it can be used with flooded or negative suction based on site needs.Q: What is the maintenance process for this centrifugal PP pump?

A: Routine inspection of bearings, seals, and impeller clearance is recommended for consistent efficiency. The pumps design facilitates easy access for service, while its leak-proof construction and corrosion resistance help minimize ongoing maintenance demands.Q: When should I choose the self-priming option for this pump?

A: The self-priming configuration is advisable when the application requires the pump to draw liquid from a level below its inlet or where frequent starting and stopping is common without manual priming. This ensures uninterrupted operation during process startups.Q: How does the IP55 protection and heavy-duty bearing design benefit industrial operations?

A: The IP55 protection rating shields internal components from dust and water ingress, extending pump life and reliability. Heavy-duty ball bearings reduce vibration and wear, supporting continuous operation and lowering the risk of unexpected breakdowns.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free