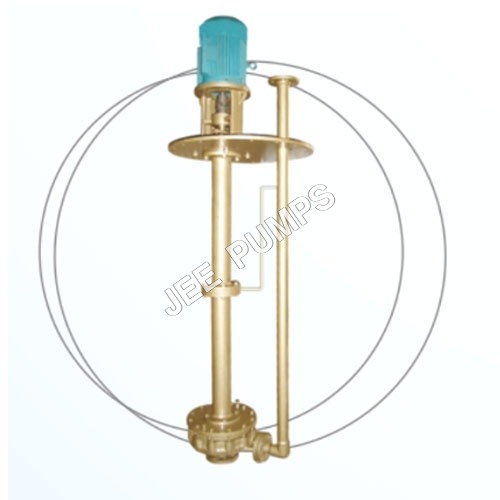

Industrial Vertical Sump Pump

Product Details:

- Flow Rate 201500 m/hr

- Head Size Up to 50 meters

- Speed 1450 2900 RPM

- Max Suction Up to 6m

- Frequency 50 Hz / 60 Hz

- Discharge Pressure Up to 6 bar

- Inlet/Outlet DN50DN250

- Click to View more

X

Industrial Vertical Sump Pump Price And Quantity

- 1 Set

Industrial Vertical Sump Pump Product Specifications

- 380V / 415V

- 50 mm to 250 mm

- Vertical Sump Pump

- Cast Iron / Stainless Steel / Alloy

- Vertical Submerged

- Centrifugal Pump

- Manual / Automatic

- Vertical Single Stage

- Max 6 bar

- Up to 6 bar

- 50 Hz / 60 Hz

- 201500 m/hr

- DN50DN250

- 80 dB(A)

- Chemical, Mining, Food Processing, Water Treatment

- 1450 2900 RPM

- Mechanical Seal / Gland Packing

- Up to 50 meters

- ISO 5199 / API 610

- Up to 6m

- 375 kW

- 201500 m/hr

- Electric

- Industrial / Effluent Treatment / Slurry

Industrial Vertical Sump Pump Trade Information

- Cash on Delivery (COD), Cheque

- 50 Set Per Month

- 1 Week

- All India

Product Description

With the help of our competent workforce, we bring forth for our clients optimum functionality Vertical Sump Pump. Our expert professionals design these sump pumps using high grade raw material. Owing to its consistent performance and high efficiency, our sump pump is highly acclaimed in the market. Vertical Sump Pump is widely used in general processing industry, acid transfer application, polymer and petrochemical industry. Clients can avail this sump pump in numerous specifications from us as per their requirements.

Features :

- Jerk free operation

- Low power consumption

- High speed operation

- Fine finish

Further Details :

- The JEE Sump Pumps are thoroughly appropriate for handling the compressed, clean or somewhat contaminated liquids such as water, effluent, cleaning products, chemicals, cooling water, hydrocarbons etc.

- These pumps are used for Dewatering of of oils, mud, gas oils etc and are applicable for loading & transferring of water and oil. The effluent and spirits of hotels, swimming pools etc are carried by the sump pumps.

- These have also Sulphuric Acid application such as the acid transfer, chemical processing, aquariums, Chloralkali etc.

- These optimal quality exclusive pumps are also utilized in Petrochemical Processing, Light Slurries, General Processing Industry, Waste Processing, for the conveyance of organic Chemicals, industrial-pumping petroleum products, solvents, vessels, chemicals, polymers, slurries etc.

Applications :

- Sulphuric Acid application, Acid Transfer, Aquariums, Chemical Processing, Chlor-alkali, General Processing Industry, Light Slurries, Organic Chemicals, Polymers, Petrochemicals Processing, etc,,

Operating Data :

- Capacity : Up to 325 M3/hr

- Head : Up to 60 Mtr.

- Discharge Size : 25 mm to 125 mm

- Temperature : 60 C

- Pump Length : Up to 4 Mtr.

- Speed : Up to 3500 RPM

- Pressure : Up to 6 kg/cm2

- M.O.C. : C.I., C.S., SS-304, SS-304L, SS-316, SS-316L, Bronze, Alloy-20, CD4MCU, Hast alloy B & C, etc

Versatile Design for Industrial Demands

Built to withstand the rigorous needs of chemical, mining, food processing, and water treatment industries, this vertical sump pump offers both performance and adaptability. Its mechanical seal or gland packing options enhance operational flexibility. An epoxy-coated finish provides extra resistance against corrosion, ensuring durability in tough environments.

Efficient Solid Handling and Energy Saving

With a maximum solid passage of up to 35 mm and a flow capacity of 201500 m/hr, this pump is ideal for slurry and effluent applications. Operating on electric power at 380V or 415V, it balances high performance and energy savings. Noise levels are kept below 80 dB(A), making it a suitable choice for continuous operation.

Advanced Protection and Control

The sump pump features IP55 or IP65 motor protection and can be configured for manual or automatic control, addressing diverse installation requirements. Lubrication systems (grease or oil) further enhance equipment longevity. Compliant with international standards, it supports safe operation under demanding conditions.

FAQs of Industrial Vertical Sump Pump:

Q: How do I choose the appropriate installation depth for my vertical sump pump?

A: Select your installation depth, between 500 mm and 2500 mm, based on the required submersion level for optimal pump performance and the sumps dimensions in your facility. Proper installation depth ensures efficient operation and prevents pump cavitation.Q: What is the benefit of using epoxy-coated vertical sump pumps in industrial environments?

A: Epoxy coating enhances the pumps resistance to corrosion and chemical attack, making it suitable for harsh industrial and effluent treatment applications. This surface finish prolongs the pumps lifespan and reduces maintenance frequency.Q: What solids size can the industrial vertical sump pump handle?

A: This pump can handle solid particles up to 35 mm in diameter, making it suitable for slurry, wastewater, and other applications where solid-laden fluids are involved.Q: Where can this vertical sump pump be used most effectively?

A: The pump is specifically designed for use in industries such as chemicals, mining, food processing, water treatment, and effluent management, thanks to its robust construction and high solid-handling capability.Q: How does the pumps lubrication system work and what maintenance does it require?

A: The pump can be lubricated by either grease or oil, as selected by the user. Regular inspection of lubrication levels and periodic replacement according to manufacturer guidelines are essential for optimal functioning and minimizing downtime.Q: When is it preferable to use mechanical seals versus gland packing?

A: Mechanical seals offer superior leakage control and require less maintenance, making them suitable for hazardous or high-pressure applications. Gland packing may be chosen for less demanding conditions or where initial cost savings are prioritized.Q: What are the advantages of centrifugal theory in this pumps operation?

A: Employing centrifugal pump theory allows this vertical sump pump to deliver consistent flow rates (201500 m/hr) and head (up to 50 meters) efficiently, providing stable and reliable movement of various fluids under industrial operating conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Vertical Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free