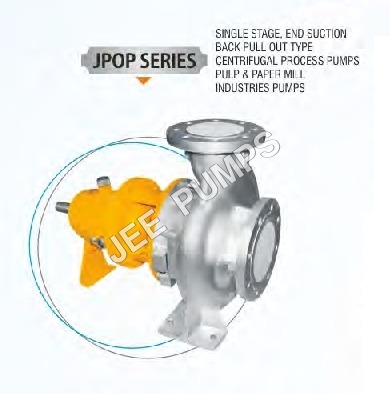

Industrial Pulp Pump

Product Details:

- Head Size 20 m

- Flow Rate 50-600 m/h

- Max Suction 7 m

- Speed 1450 / 2900 rpm

- Inlet/Outlet 100mm / 80mm

- Voltage 380V/415V

- Working Temperature Up to 90C

- Click to View more

X

Industrial Pulp Pump Price And Quantity

- 1 Set

Industrial Pulp Pump Product Specifications

- 7 m

- Mechanical Seal/Gland Packing

- 50-600 m/h

- 20 m

- 2.5 bar

- 100mm / 80mm

- 1450 / 2900 rpm

- Up to 90C

- Horizontal

- Electric

- Single Suction

- 380V/415V

- Single Stage

- Max 0.25 MPa

- 11 kW

- Pulp Pump

- 50/60 Hz

- DN100 / DN80

- 75 dB(A)

- Stainless Steel / Cast Iron

- Up to 600 m/h

- Industrial Pulp Handling

- ISO 5199

- Corrosion-resistant, Heavy-duty design

- Centrifugal Pump

- Self-priming

- Paper Mills, Chemical Plants, Sugar Industry

- Manual/Automatic

Industrial Pulp Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

As per the variegated requirements of our clients, we are offering a broad collection of Pulp Pump. The given range of pulp pump is checked by quality examiners in order to deliver a flawless range from our end. This pulp pump is manufactured with advance technology in compliance with market norms. Our pulp pump is provided in numerous specifications as per the needs of customers at nominal rates.

Applications :-

- Chest Pump

- Refineries Pump

- Fan Pump

- Centri Cleaner Pump

- Back Water Pump

- Separator Pump

- Couch Pit Pump

- Turbo Feed Pump

- Stock pump

Operating Data :-

- Capacity: Up to 640m3/hr

- Head: Up to 55 Mtr.

- Discharge Size: 25 mm to 200 mm

- Temperature: Up to 250 C

- Speed: Up to1500 rpm

- Pressure: Up to 5.5 kg/cm2

- Impellers: Open & Semi Open Type

- Consistency: Up to 7 %

- M.O.C.: C.I., C.S., SS-304, SS-304L, SS-316, SS-316L, Bronze, Alloy-20, CD4MCU, Hast alloy B & C, etc

Advanced Engineering for Industrial Applications

Specifically tailored for the rigorous demands of pulp transport, this pump serves industries that require uninterrupted efficiency and durability. Its centrifugal design and high-quality components support long-term, reliable operation, making it suitable for continuous, heavy-duty usage. The pumps mechanical seal or gland packing solution ensures minimal leakage, protecting equipment and maintaining safety standards.

Robust Construction and Corrosion Resistance

Built using high-strength steel for shafts and anti-corrosive coatings, the pump withstands aggressive process fluids and harsh industrial environments. The use of stainless steel or cast iron materials enhances its resilience against wear and chemical attack, ensuring high performance even with abrasive pulp mixtures.

Flexible Operation and Easy Maintenance

Equipped with grease or oil lubrication systems and flexible coupling, the pump simplifies upkeep and accommodates varied operational requirements. Heavy-duty ball bearings and horizontal mounting make maintenance straightforward, while the IP55 motor protection ensures safe, reliable function even in challenging settings.

FAQs of Industrial Pulp Pump:

Q: How does the Industrial Pulp Pump handle solid contents up to 6%?

A: The pump utilizes an open or semi-open impeller type, allowing it to efficiently transfer pulp mixtures containing up to 6% solid content without clogging or performance loss. This impeller design is ideal for industrial applications with high solid loading.Q: What are the main benefits of using this pulp pump in paper mills and chemical plants?

A: This pump offers robust corrosion resistance, long service life, and the capability to operate continuously at high capacities. Its heavy-duty construction and mechanical seal options minimize maintenance needs and ensure reliable performance in demanding environments.Q: When should grease or oil lubrication be used for this pump?

A: Choice between grease and oil lubrication depends on the operational environment and maintenance schedule. Grease-lubricated bearings offer easier maintenance, while oil lubrication provides better cooling in high-speed or heavily loaded scenarios.Q: Where can the Industrial Pulp Pump be installed within a facility?

A: Designed for floor-mounted, horizontal installation, this pump easily integrates into pulp handling systems in paper mills, chemical plants, sugar factories, and other industrial sites requiring continuous material transfer.Q: What is the process for maintaining the pumps seals and bearings?

A: Regular inspection and replacement of mechanical seals or gland packing ensure minimum leakage. Bearings should be checked for wear and lubricated with appropriate grease or oil, as recommended in the maintenance manual.Q: How does the pumps motor protection (IP55) enhance safety during operation?

A: The IP55-rated motor protection safeguards against dust ingress and low-pressure water jets, allowing safe operation in wet or dusty industrial environments and extending the motors service life.Q: What advantages does the anti-corrosive paint offer for industrial usage?

A: Anti-corrosive paint shields the pumps surfaces against chemical exposure, moisture, and environmental wear, significantly reducing rust and corrosion, which prolongs the operational life even in harsh industrial conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Pulp & Paper Mill Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM