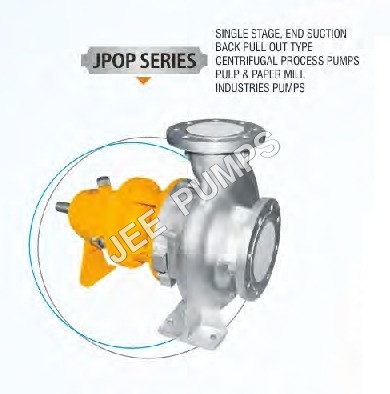

Pulp and Paper Stock Pump

Product Details:

- Discharge Pressure Up to 16 bar

- Max Suction Up to 7 meters

- Mounting Type Baseplate Mounted

- Flow Rate 15 m/hr to 2500 m/hr

- Working Temperature Up to 120C

- Noise Level Below 85 dB

- Voltage 415 V / 380 V / 220 V (three-phase or as specified)

- Click to View more

X

Pulp and Paper Stock Pump Price And Quantity

- 1 Set

Pulp and Paper Stock Pump Product Specifications

- 15 m/hr to 2500 m/hr

- End Suction

- Horizontal, Single-Stage

- 15 m/hr to 2500 m/hr

- Baseplate Mounted

- Up to 16 bar

- Up to 7 meters

- ISO 5199 / DIN 24256 / As per customer requirement

- 415 V / 380 V / 220 V (three-phase or as specified)

- Mechanical Seal / Gland Packing

- Up to 120C

- Below 85 dB

- DN80 DN300

- 1450 rpm / 2900 rpm

- Centrifugal Pump

- Optional Automation / Manual Control

- Self / Manual Priming (depending on model)

- Electric

- Suitable for handling fibrous pulp stock; High efficiency; Corrosion and wear resistance; Low maintenance; Designed for continuous operation

- Pulp and Paper Industry (stock transfer, white water circulation, etc.)

- N/A (Electric Pump)

- Up to 16 bar

- 80 mm / 65 mm to 300 mm / 250 mm (various sizes available)

- Cast Iron / Stainless Steel / Ductile Iron

- 50 Hz / 60 Hz

- Pulp & Paper Stock, Clean Water, Industrial Liquids

- 3 HP to 250 HP

- Centrifugal Process Pump

- Up to 150 meters

Pulp and Paper Stock Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

Pulp & Paper Stock Pump

Applications :

- Stock pump, Refiners pump, Fan pump, Centri cleaner pump, Back water pump, Separator pump etc

- ETP STP & Waste water treatment plant fertilizers, Cement & Steel industries

- For pumping chemicals with solids in suspension polluted liquids widely used for public and civil engineering.

Operating Data :

- Capacity: Up to 640m3/hr

- Head: Up to 54 Mtr.

- Size: Up to 8

- Temperature: Up to 250 C

- Speed; Up to1500 rpm

- M.O.C.: C.I., C.S., SS-304, SS-304L, SS-316, SS-316L, Bronze, Alloy-20,

- CD4MCU, Hast alloy B & C, etc

Versatile Handling for High Consistency Applications

This pump accommodates a wide range of pulp consistencies, handling up to 6% fibrous stock without clogging. Its semi-open or closed impeller ensures smooth operation for both pulp and clean water. This versatility makes it ideal for stock transfer, white water circulation, and handling various industrial liquids in pulp and paper processing plants.

Durable Construction & Corrosion Resistance

Built with heavy-duty bearings and available in stainless steel, cast iron, or ductile iron, the pump excels in demanding industrial environments. An epoxy coating provides outstanding resistance to corrosion, making it suitable for continuous use in harsh process conditions. Its robust shaft and flexible couplings ensure stable, long-term operation.

Efficiency and Compliance with Global Standards

With discharge pressures up to 16 bar and capacities up to 2500 m/hr, this centrifugal pump delivers high efficiency, low noise, and minimal maintenance. It complies with ISO 5199, DIN 24256, and CE standards, backed by ISO 9001:2015 quality certification. Options for automation and manual control further enhance operational flexibility.

FAQs of Pulp and Paper Stock Pump:

Q: How does the non-clogging impeller benefit pulp and paper processing?

A: The semi-open or closed, non-clogging impeller is specially designed to handle fibrous pulp stocks up to 6% consistency, significantly reducing blockage. This ensures uninterrupted transfer and processing of pulp, enhancing operational uptime and efficiency in paper manufacturing plants.Q: What installation requirements are needed for this centrifugal process pump?

A: Installation is straightforward, as the pump comes in a horizontal, foot-mounted configuration and is supplied baseplate mounted. It requires electrical power (three-phase, 415V/380V/220V as per specification) and is designed for end-suction piping. All necessary connections for inlet/outlet and control systems are detailed in the installation manual.Q: When should oil or grease be used for bearing lubrication?

A: The appropriate lubricanteither grease or oildepends on the operations temperature, speed, and site maintenance preferences. The heavy-duty bearings are compatible with both, but for high-temperature or high-speed operations, oil lubrication is advisable for extended service intervals.Q: Where can this pump be applied apart from pulp stock transfer?

A: Besides pulp and paper stock handling, this pump is effective for white water circulation, clean water delivery, and transfer of industrial liquids in similar process industries. Its robust material and corrosion-resistant coating make it versatile for various liquid transfer applications.Q: What is the typical process for startup and operation of the pump?

A: The pump can be primed manually or automatically (subject to model), and after ensuring proper priming, you can start the unit with the correct electrical supply. The direction of rotation should always be checked (clockwise from drive end). Continuous-duty design means it is suited for ongoing operation in industrial settings.Q: How does the epoxy coating and stainless steel construction provide benefits?

A: The epoxy paint offers a strong barrier against corrosion, while the option of stainless steel shaft and components enhances resistance to both wear and chemical attack. This combination ensures reliable performance, reduces maintenance frequency, and prolongs service life in aggressive industrial environments.Q: What certifications and protections does the pump have for quality assurance?

A: The pump is ISO 9001:2015 and CE certified, constructed as per ISO 5199 and DIN 24256 standards. It features insulation classes F or H and protection classes IP54/IP55, ensuring both electrical safety and operational reliability in compliance with international quality expectations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Pulp & Paper Mill Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM