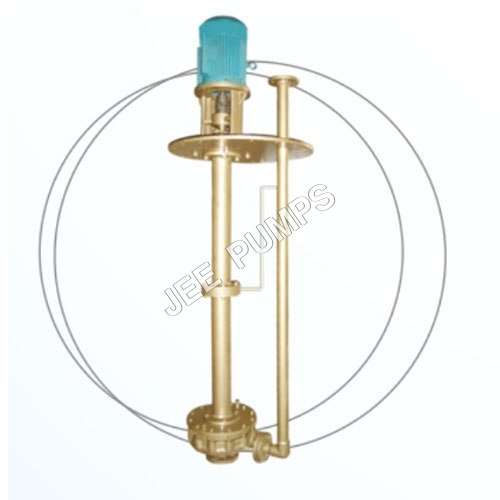

Industrial JEE MAKE Vertical Pumps

Product Details:

- Caliber As per design

- Features Corrosion Resistant, High Efficiency, Easy Maintenance

- Frequency 50 Hz

- Theory Centrifugal Pump

- Control System Manual / Automatic

- Inlet/Outlet As per requirement

- Speed 1450 / 2900 rpm

- Click to View more

Industrial JEE MAKE Vertical Pumps Price And Quantity

- 1 Set

Industrial JEE MAKE Vertical Pumps Product Specifications

- 0.5 to 75 kW

- Centrifugal Pump

- Industrial

- Mechanical Seal

- 50 Hz

- As per design

- Corrosion Resistant, High Efficiency, Easy Maintenance

- Vertical Suction

- Up to 7 Bar

- Electric

- Manual / Automatic

- Cast Iron / Stainless Steel

- Vertical

- Up to 500 m3/hr

- Vertical Centrifugal

- 1450 / 2900 rpm

- As per requirement

- Up to 500 m3/hr

- Up to 70 m

- Non Self-Priming

- Variable

- Base Mounted

- Up to 80C

- 415 V

- Chemical, Water, Petroleum, Effluent

- 5 M

- IS: 5120 / ISO: 5199

- Low

Industrial JEE MAKE Vertical Pumps Trade Information

- 50 Set Per Month

- 1 Week

Product Description

JEE MAKE Vertical Pumps

JEE Make Vertical Pumps is counted to be the best equipment for moving fluids using mechanical action because of its rigid construction and excellent performance. The mentioned pump is suitable to be used for both hot and cold water circulation. For this reason, this is highly demanded in the market. Designed and engineered to meet all the requirements of our clients, this pump is made of material of high grade. Compact in size, our offered JEE Make Vertical Pumps is one of the best known products to even fit in the smaller spaces of industrial environments.

Features

- Possesses the capability to withstand different challenging conditions.

- Affordable and innovative solution to transfer fluids.

- Can be used to prevent noise and leakage free operations.

- Highly reliable and durable while ensuring efficient performance.

Specification

|

Length |

Up to 4 mtrs |

|

Motor Horsepower |

20 - 140 HP |

|

Head |

15 to 50 m |

|

Motor Phase |

Three Phase |

|

Brand |

Jee pumps |

|

Number Of Stages |

Single-stage Pump |

|

Capacity |

Up to 350 m3/hr |

|

Model Number/Name |

JVSP |

|

Temperature |

Up to 160 deg C |

|

Speed |

Up to 3500 RPM |

|

Pressure |

Up to 10 kg / cm2 |

High Performance for Varied Applications

JEE MAKE Vertical Pumps deliver superior reliability and efficiency in applications such as water treatment, chemical processing, petroleum handling, and effluent management. Designed according to IS: 5120 and ISO: 5199 standards, these pumps are well-suited to both demanding industrial and commercial environments, providing high flow rates and stable operation even with variable discharge pressures.

Superior Design for Continuous Operation

With features like corrosion-resistant materials, mechanical seals, and options for fully enclosed or semi-open impellers, these centrifugal pumps are engineered for continuous duty. The vertical suction structure and base-mounted unit ensure easy installation and low noise, while forced or natural cooling options provide optimal thermal management during prolonged operation.

Flexible Options to Meet Your Needs

The pumps can be configured with shaft materials, protection grades, and mounting types to suit specific project requirements. Whether manual or automatic control is required, and regardless of whether indoor or outdoor installation is needed, JEE MAKE Vertical Pumps offer flexibility and high efficiency to adapt to various industrial scenarios.

FAQs of Industrial JEE MAKE Vertical Pumps:

Q: How do I select the appropriate impeller type for my application?

A: Choosing between a fully enclosed or semi-open impeller depends on the fluids nature. Fully enclosed impellers are ideal for handling clean liquids, while semi-open impellers work best with fluids containing suspended solids up to 25 mm. Assess your applications requirements for optimal performance.Q: What are the advantages of forced cooling versus natural cooling in these vertical pumps?

A: Forced cooling is recommended for high-temperature or extended continuous duty applications, as it accelerates heat dissipation and safeguards motor integrity. Natural cooling is adequate for standard operations with moderate temperatures and ambient conditions.Q: When should I consider stainless steel versus EN8 for the pump shaft material?

A: Stainless steel is preferable in corrosive environments or chemical applications, ensuring enhanced durability. EN8 is suitable for general industrial use with non-corrosive fluids, offering strength at a competitive cost.Q: Where can these vertical centrifugal pumps be installed?

A: JEE MAKE Vertical Pumps are versatile for both indoor and outdoor settings thanks to their IP55 ingress protection and robust construction. Be sure to install them in areas with proper access for maintenance and according to safety regulations.Q: What is the recommended process for maintaining these pumps?

A: Routine maintenance involves checking lubrication (grease or oil as specified), inspecting mechanical seals, ensuring the motors cooling system works effectively, and periodically verifying alignment and base mounting. Follow the manufacturers detailed manual for preventative care.Q: How can these pumps benefit my industrial facility?

A: These pumps provide high efficiency, easy maintenance, and reliable performance under continuous duty. Their corrosion-resistant builds and adaptability to different fluids and solid content help reduce downtime and lifecycle costs.Q: What is the maximum flow and head these pumps can handle?

A: The industrial vertical pumps can achieve flow rates up to 500 m/hr and head sizes up to 70 meters, making them suitable for a wide range of industrial processes with variable discharge pressure requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM