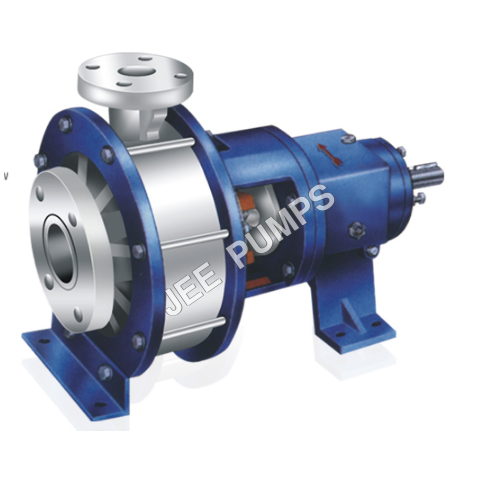

Industrial JPP Series Polypropylene Pumps

22000 INR/Piece

Product Details:

- Caliber 25 to 65 mm

- Theory Centrifugal Pump

- Head Size Upto 28 Meter

- Inlet/Outlet 1 to 2.5 (BSP/NPT Threaded Ends or Flange)

- Max Suction Up to 3.5 Meter

- Control System Manual/Automatic

- Mounting Type Base Plate Mounted

- Click to View more

X

Industrial JPP Series Polypropylene Pumps Price And Quantity

- 1 , , Piece

- 22000 INR/Piece

Industrial JPP Series Polypropylene Pumps Product Specifications

- Industrial, Chemical, Wastewater, Effluent Transfer

- 25 to 65 mm

- Polypropylene (PP)

- Centrifugal Pump

- Up to 2.8 kg/cm2

- Upto 28 Meter

- 0.5 HP to 5 HP

- 1 to 2.5 (BSP/NPT Threaded Ends or Flange)

- Chemical Process, Acid Transfer, Industrial Liquids Handling

- Electric

- Up to 3.5 Meter

- Manual/Automatic

- Upto 28 m3/hr

- Base Plate Mounted

- Single Stage or Multi Stage

- Upto 2.8 bar

- Self or Manually primed

- ISO 9001:2015 Certified

- Mechanical Seal / Gland Packing

- Upto 28 m3/hr

- Low

- 220-415V

- Up to 2900 rpm

- Upto 80C

- N/A (Electric Operated)

- JPP Series Polypropylene Pump

- Corrosion Resistant, Leak-Proof Design, Lightweight, Easy Maintenance

- Self Priming / Non-Self Priming

- 50/60 Hz

Industrial JPP Series Polypropylene Pumps Trade Information

- 1 , , Piece Per Day

- 1 Days

Product Description

Specification

| Capacity | Up to 50 m3/hr |

| Discharge Size | 25 mm to 50 mm |

| Material Of Construction | PP, UHMWPE |

| Pressure | Up to 4.5 kg/cm2 |

| Speed | Up to 3500 rpm |

| Temperature | 80 Deg C |

| Head | Up to 45 mtr |

Robust Chemical Compatibility

Constructed from high-quality polypropylene, the JPP Series pumps offer strong resistance against various chemicals and corrosive liquids. Their non-metallic design and encapsulated SS-304/SS-316 shaft make them suitable for challenging environments where traditional pumps may not endure, extending their service life and reliability.

Flexible Impeller and Seal Choices

With closed or semi-open impeller types and mechanical seal or gland packing options (PTFE/Viton/Ceramic), users can tailor the JPP Series pumps to specific operational demands. This flexibility ensures excellent performance across diverse industrial applications, from acid transfer to wastewater treatment.

Efficient, Low-Maintenance Operation

Floor-mounted and base plate-installed, these electric pumps feature air-cooled motors with IP55 protection, supporting continuous operation with minimal downtime. Self-priming and non-self-priming variants simplify installation, while low maintenance requirements reduce overall lifecycle costs for users.

FAQs of Industrial JPP Series Polypropylene Pumps:

Q: How do the JPP Series Polypropylene Pumps ensure corrosion resistance in harsh chemical environments?

A: The pumps are made from polypropylene, a robust non-metallic material known for its resistance to a wide range of chemicals and corrosive liquids. The optional PTFE, Viton, or Ceramic seals further enhance protection, making these pumps suitable for acid, chemical, and effluent transfer.Q: What are the main advantages of using a closed or semi-open impeller in the JPP Series pumps?

A: A closed impeller offers high efficiency and is ideal for clean liquids, while a semi-open design handles liquids with suspended solids up to 5 mm, preventing clogging. This versatility allows users to select the appropriate model for their specific fluid and application requirements.Q: When should I opt for self-priming versus non-self-priming models?

A: Choose a self-priming pump when the application requires suction lift, such as drawing liquid from below the pump level or when the pump is not flooded. Non-self-priming versions are recommended for flooded suction installations, where the liquid supply is at or above pump level.Q: Where can the JPP Series Polypropylene Pump be installed in industrial settings?

A: The pump is designed for floor mounting on a base plate, making it suitable for factories, processing plants, wastewater treatment facilities, and chemical transfer stations. Its simple installation and compact footprint enable flexible placement within diverse industrial environments.Q: What maintenance practices help ensure long service life of the JPP Series pumps?

A: These pumps are engineered for easy maintenance with quick-access designs and corrosion-resistant materials. Routine inspections, timely seal checks, and periodic cleaning of the impeller and casing help ensure optimal performance while minimizing downtime and maintenance costs.Q: How does the IP55 motor protection contribute to safe and reliable pump operation?

A: IP55 motor protection guards against dust ingress and low-pressure water jets, making the electric motor suitable for challenging industrial conditions. This ensures safe, continuous operation, especially in moist or dusty atmospheres common in chemical and wastewater plants.Q: What process and industries benefit most from using the JPP Series Polypropylene Pumps?

A: Industries such as chemical processing, pharmaceuticals, wastewater treatment, and acid transfer benefit from these pumps due to their corrosion-resistant design, leak-proof construction, and ability to handle a variety of aggressive or contaminated liquids with ease.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Polypropylene Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free