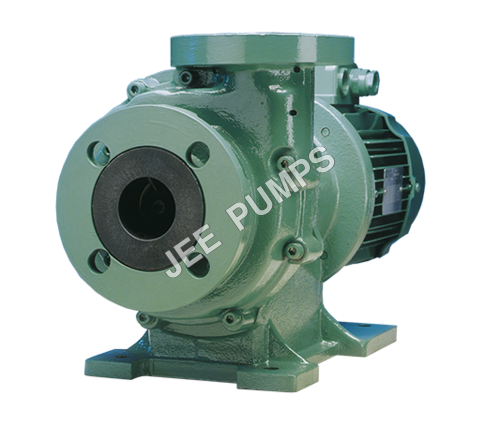

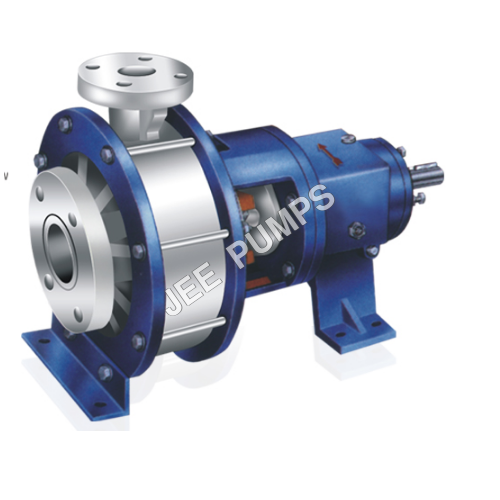

Industrial HCL Acid Pump

Product Details:

- Fuel Tank Capacity N/A - Electric Powered

- Head Size 8~38 m

- Flow Rate 1~16 m/h

- Control System Manual / Automatic

- Voltage 220V / 380V

- Speed 2800 RPM

- Discharge Pressure Up to 4 Bar

- Click to View more

Industrial HCL Acid Pump Price And Quantity

- 45000.00 INR/Set

- 01 Set

Industrial HCL Acid Pump Product Specifications

- DN25

- 1~16 m/h

- Base Mounted

- 3.5 m

- Mechanical Seal

- End Suction

- Polypropylene (PP), FRP lined, SS

- -10C to +80C

- 0.37 kW to 5.5 kW

- 50/60 Hz

- Corrosion Resistant, Leak-proof, Heavy Duty, Low Maintenance

- Up to 4 Bar

- Electric

- Horizontal, Single-stage

- 1~16 m/h

- Manual / Automatic

- 220V / 380V

- 2800 RPM

- Industrial Acid Transfer

- ISO 2858

- Self-Priming or Non-Self-Priming (as per model)

- 8~38 m

- N/A - Electric Powered

- Hydrochloric Acid Handling, Chemical Transfer, Acidic Liquid Circulation

- Centrifugal Pump

- 70 dB

- Up to 4 Bar

- 25 mm / 25 mm

- Horizontal Centrifugal

Industrial HCL Acid Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

This clear and colorless inorganic, Hydrochloric acid finds massive use in industrial applications such as oil well acidizing, steel pickling and in the food industry, etc. Understanding the important usage of this acid in aforementioned applications and its smooth pumping at room temperature, we offer HCL Acid Pump. Our provided pump is manufactured strictly according to industrial norms of quality. This pump is brilliantly designed, developed and manufactured to perfectly handle hydrochloric acid. The working of our pump is highly impressive and it stands tall on requirements such as concentration of the acid in use, its specific gravity and acid temperature, which are considered for right selection of HCL Acid Pump.

Features

- It is perfect for use in high temperature demanding industrial applications.

- Provided pump is noted for being highly resistant to cracking and stress.

- Offered pump boasts of having a strong construction and enhanced durability.

- This quality approved pump is widely acclaimed for its supreme performance.

Specification

| Capacity | Up to 300 m3/hr. |

| TDH Head | Up to 64 mtr. |

| Temperature | 80 to 140 deg C |

| Speed (at 60 Hz) | 1750 / 3500 rpm |

| Speed (at 50 Hz) | 1450 / 2880 rpm |

Reliable Acid Handling Performance

Engineered for transferring hydrochloric acid and similar aggressive chemicals, this pump ensures minimal leakage, excellent corrosion resistance, and steadfast performance. Its robust construction, ISO 2858 conformity, and base-mounted design make it ideal for various industrial transfer and circulation applications.

Customizable for Your Facility

Available in multiple configurations, this pump offers threaded or flanged connections, customizable color schemes, and material options including polypropylene, FRP lined, or stainless steel. Select from self-priming or non-self-priming models to match your operational needs, ensuring compatibility with your existing system.

Easy Operation and Maintenance

Featuring straightforward installation in a horizontal position and designed with easy-to-maintain components, this pump supports both manual and automatic operation. Its heavy-duty ball bearings and leak-proof mechanical seal help ensure long service intervals and minimized downtime.

FAQs of Industrial HCL Acid Pump:

Q: How does the Industrial HCL Acid Pump handle corrosive and acidic fluids safely?

A: The pump is constructed with corrosion-resistant materials like polypropylene, FRP lining, or stainless steel and uses a mechanical seal, ensuring reliable containment and leak-proof operation even when handling aggressive chemicals such as hydrochloric acid.Q: What installation options are available for this pump?

A: This pump is designed for horizontal, base-mounted installation. It offers both threaded and flanged connection types for easy integration into your facility, supporting various industrial chemical transfer systems.Q: When should I choose a self-priming vs. a non-self-priming model?

A: Select a self-priming model if your application requires the pump to start without manually filling the suction line, especially when handling fluids from below pump level. Non-self-priming models are suitable where prerequested priming is not an issue.Q: Where is this pump typically used?

A: The pump is ideal for hydrochloric acid handling, chemical transfer, acidic liquid circulation, and other industrial processes in chemical plants, manufacturing facilities, and fluid transfer stations.Q: What is the maximum solid passage and why is it important?

A: The pump can handle solids up to 5 mm in size, allowing it to transfer fluids that may contain minor particulate matter without risking clogging or damage to the impeller.Q: How easy is maintenance for this acid pump?

A: Designed for easy upkeep, the pump features accessible components, reliable seals, and heavy-duty bearings. This reduces downtime and simplifies regular maintenance procedures.Q: What are the main benefits of using this pump for hydrochloric acid transfer?

A: Key advantages include high corrosion resistance, low maintenance, reliable leak-proof performance, customizable configurations, and adherence to ISO 2858 standards, ensuring both safety and durability in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM