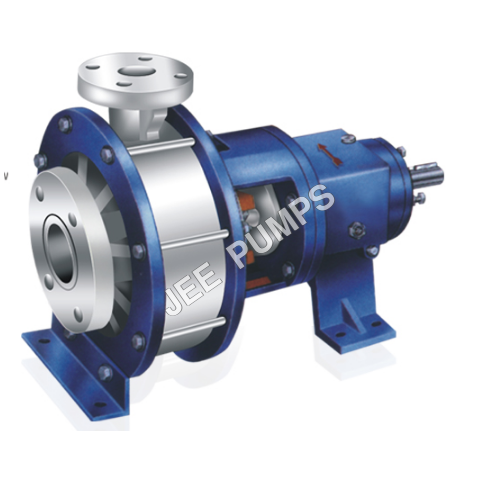

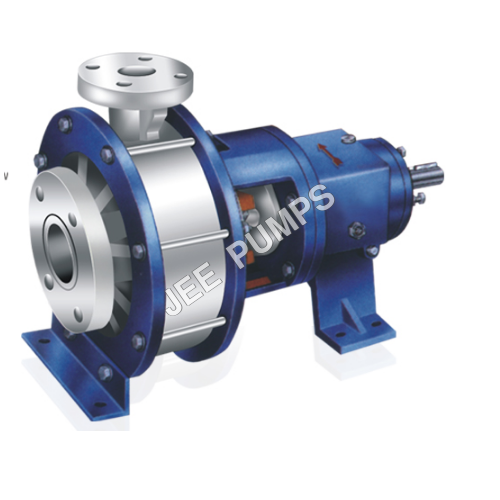

Industrial HCL Transfer Pump

Product Details:

- Working Temperature Up to 80C

- Discharge Pressure 2.5 Bar (max)

- Theory Centrifugal Pump

- Control System Manual / Automatic

- Inlet/Outlet 1.5 x 1.5 (40 x 40 mm)

- Voltage 220V / 380V

- Speed 2800 RPM

- Click to View more

X

Industrial HCL Transfer Pump Price And Quantity

- 01 Set

Industrial HCL Transfer Pump Product Specifications

- 40 mm

- Mechanical Seal / PTFE

- Up to 3 meters

- Centrifugal Pump

- 50 Hz / 60 Hz

- Manual / Automatic

- Polypropylene (P.P.), Stainless Steel

- Base Mounted

- Single Stage

- ISO 9001 Certified

- Industrial HCL Acid Transfer

- Low Noise Operation

- 2800 RPM

- Electric

- Horizontal

- Chemical Industries, Acid Handling

- Up to 80C

- 2.5 Bar (max)

- 1.5 x 1.5 (40 x 40 mm)

- 220V / 380V

Industrial HCL Transfer Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

We have acquired the reputation of being one of the reputed manufacturers, suppliers and exporters of superior quality HCL Transfer Pump. As these pumps are made using finest quality raw material, these have high strength, high functionality and longer operational life. Owing to their easy installation, high working efficiency and negligible maintenance, our transfer pumps are highly demanded in the market. HCL Transfer Pump is widely being used in chemical, mining, sugar and paper industry.

Applications :-

- Water treatment plant, Effluent treatment plant, electro plating, pickling & steel Rolling mills,

- Excellent for transfer and loading and "unloading like HCL, Sulphuric Acid/Alkali, Caustic liquid

- Scrubbing of corrosive gases like NH3, CO2, SO2, L2, F2, Br2, CI2, etc,,,,

- For handling liquids in various like textile, paper, cellulose, sugar, steel, food, having, Temperature range, materials etc,,

- Ideal for circulation for pickling line & scrubber in Steel plant

- High capacity transfer pump, filter press for dyes & chemical, descaling, Oil & other fuels

Operating Data :-

- Capacity : Up to 50 m3/hr

- Head : Up to 45 Mtr.

- Discharge Size : 25 mm to 50 mm

- Temperature : 80 C

- Speed : Up to 3500 RPM

- Pressure : Up to 4.5 kg/cm2

- M.O.C. : PP, UHMWPE

Robust Acid Handling Solution

Engineered for durability, this transfer pump is suitable for continuous operation in harsh chemical environments, transferring HCL and similar aggressive acids efficiently. The housing is constructed from heavy-duty PP and stainless steel, offering corrosion resistance and mechanical strength. Operating at up to 80C and 2.5 bar pressure, its design is optimized for safety and longevity. The IP55 protection class further safeguards against environmental factors, making it ideal for industrial usage.

Flexible Installation and Operation

With horizontal suction type and direct-coupled mounting, this pump provides easy installation and dependable performance. Compatible with both flange and threaded connections, it suits a variety of system setups. Its control systems offer both manual and automatic options, and the pump meets ISO 9001 standards. Designed for versatile voltage and frequency input, its ready for deployment across chemical industries in India and beyond.

FAQs of Industrial HCL Transfer Pump:

Q: How does the industrial HCL transfer pump ensure safe and continuous operation?

A: The pump uses heavy-duty polypropylene housing and mechanical/PTFE seals, protecting against corrosion and leaks. Its IP55-rated enclosure resists dust and moisture, while continuous-duty construction allows for non-stop acid transfer. The robust direct-coupled design and stringent ISO 9001 standards add extra layers of operational safety and reliability.Q: What types of fluids and applications can this pump handle effectively?

A: This pump is designed specifically for industrial HCL acid transfer but also reliably moves other compatible chemicals with viscosity up to 100 cps and particles up to 5 mm in size. Its commonly used in chemical industries, acid handling systems, and other process industries requiring safe and efficient acid conveyance.Q: When should this pump be chosen over other transfer pump types?

A: Select this pump when continuous acid transfer, high chemical compatibility, and low maintenance are key priorities. Its durable construction, wide fluid compatibility, and operational flexibility make it an excellent choice in demanding applications involving hazardous chemicals and high temperatures (up to 80C).Q: Where can this pump be installed within an industrial system?

A: The pump features a base-mounted, horizontal installation, ideal for placement alongside process tanks or as part of integrated chemical handling systems. Its flange and threaded connections make integration into new or existing pipelines straightforward, particularly in Indian industrial environments.Q: What is the process for routine maintenance of this pump?

A: Routine maintenance involves checking the condition of seals (mechanical/PTFE), inspecting for any leaks, ensuring the direct-coupled motor alignment, and cleaning the pump housing to prevent acid buildup. Low noise and wear-resistant materials help reduce maintenance intervals, while a qualified technician should conduct periodic assessments for optimal performance.Q: How does using this pump benefit chemical industry operations?

A: Deploying this pump streamlines acid transfer with increased operational safety, minimal downtime, and efficient handling of corrosive fluids. Its single-stage, energy-efficient design, reliable mechanical seals, and standardized components contribute to reduced operating costs and safer workplace conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Polypropylene Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM