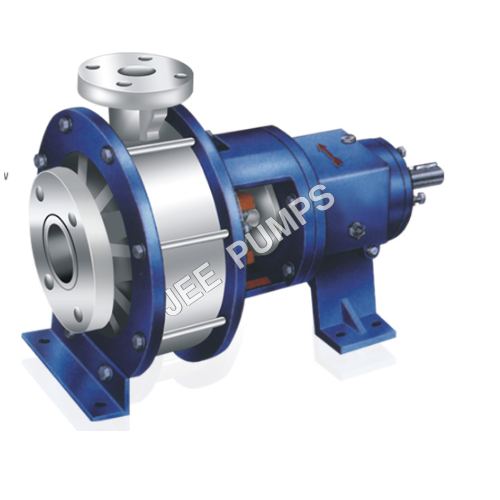

Polypropylene High Speed Process Pump

Product Details:

- Max Suction Up to 3.5 m

- Head Size Up to 42 m

- Theory Centrifugal Pump

- Noise Level <70 dB(A)

- Inlet/Outlet 25 mm x 25 mm to 100 mm x 100 mm

- Speed 2880 RPM

- Frequency 50 Hz

- Click to View more

Polypropylene High Speed Process Pump Price And Quantity

- 22000.00 INR/Set

- 01 Set

Polypropylene High Speed Process Pump Product Specifications

- 0.5 HP to 10 HP

- Mechanical Seal

- High speed, Corrosion resistant, Low maintenance, Rigid construction

- Manual/Automatic

- Up to 4.2 kg/cm

- Base Plate Mounted

- ISI Standard

- Up to 4.2 kg/cm

- Chemical, Effluent, Acid, Electroplating, Pharmaceutical

- Up to 60 m/hr

- Self-Priming (Optional)

- Up to 80C

- Polypropylene

- Electric

- 220-240 V

- 25 mm x 25 mm to 100 mm x 100 mm

- 2880 RPM

- 50 Hz

- DN 25DN 100

- Process Pump

- Centrifugal Pump

- Single Stage

- Corrosive Chemical Process & Transfer

- <70 dB(A)

- Up to 60 m/hr

- End Suction

- Up to 3.5 m

- Up to 42 m

Polypropylene High Speed Process Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Made using high quality polypropylene, our offered Polypropylene High Speed Process Pump is acclaimed to be the most efficient performing pump in the entire range. Technologically advanced manufacturing assists us in providing only the best quality pump to our clients that also offers lasting operational life. The accurate dimensions ensure that it is easily installed without any hassle. Rugged construction, innovative design and smooth operations are some of the attributes that make our Polypropylene High Speed Process Pump the best buy. Moreover, the mentioned pump is highly demanded for acidic water transfer, electroplating, pharmaceutical, chemical process and more.

Advantages

- Provided pump is known for its simple structure and lower maintenance.

- Unmatched quality at such reasonable price.

- Good quality material is used in the engineering of our pump.

- Mentioned pump is widely appreciated for its dimensional accuracy.

Specification

| Capacity | Up to 50 m3/hr |

| Head | Up to 45 mtr |

| Temperature | 80 deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 4.5 kg/cm2 |

| Discharge Size | 25 mm to 50 mm |

Robust Corrosion Resistance for Industrial Applications

This high-speed polypropylene process pump offers remarkable protection against acids and corrosive chemicals, making it highly suitable for chemical, effluent, and pharmaceutical industries. Its superior material integrity and heavy-duty construction minimize the risk of wear, ensuring extended service life even in challenging environments.

Flexible and High-Performance Operation

Designed to support both single and three-phase motors, the pump provides a flow rate of up to 60 m/hr and pressures up to 4.2 kg/cm. The centrifugal, single-stage structure facilitates quick, efficient liquid transfer, while the optional self-priming feature and secure mechanical seals enable versatile installation and operation.

Low Maintenance and User-Friendly Design

With a direct-coupled drive and totally enclosed fan-cooled (TEFC) motor, this process pump significantly reduces operational noise (<70 dB), vibration, and heat. Heavy-duty ball bearings and a robust base plate mounting system further simplify routine maintenance, ensuring reliable, hassle-free pump performance.

FAQs of Polypropylene High Speed Process Pump:

Q: How does the polypropylene construction benefit chemical process industries?

A: Polypropylene provides exceptional chemical resistance, making the pump suitable for transferring corrosive acids, chemicals, and effluents without degradation. This enhances equipment longevity and reduces the risk of leaks or contamination in harsh process environments.Q: What is the process for installing and commissioning this high-speed process pump?

A: Installation involves securing the pump on a base plate, ensuring proper horizontal alignment, and connecting the inlet/outlet pipework. Electrical connections for either single or three-phase supply should be handled by a qualified technician. Priming (if required) and startup should follow the manufacturers guidelines for safe operation.Q: When should a close or semi-open impeller be used in this pump?

A: A close impeller is ideal for clean liquids, offering higher efficiency, while a semi-open impeller is preferred for fluids containing suspended solids or light slurries, reducing clogging and facilitating easier maintenance during critical process transfers.Q: Where can this pump be utilized beyond chemical processing?

A: The pump is versatile and can be used in effluent treatment plants, electroplating units, pharmaceuticals, and industrial wastewater handlinganywhere corrosion resistance and high-speed liquid transfer are required.Q: What maintenance is required for optimal performance?

A: Routine inspection should focus on bearing condition, seal integrity, and alignment. Periodic cleaning of the impeller and casing, alongside lubrication checks, will help the pump maintain its high efficiency and extend its operational lifespan.Q: How does the totally enclosed fan cooled (TEFC) motor improve safety and performance?

A: The TEFC motor design protects internal components from dust, moisture, and chemical exposure, ensuring safer operation and prolonging motor life. It also keeps heat dissipation efficient, reducing the risk of electrical faults or overheating.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free