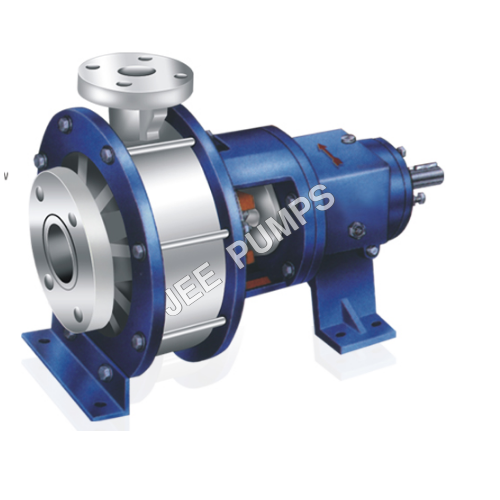

Industrial Liquid Transfer Pump

Product Details:

- Speed 2800 rpm

- Frequency 50 Hz

- Inlet/Outlet 25 mm / 25 mm

- Voltage 220-240 V

- Max Suction 6-8 meters

- Mounting Type Base Mounted

- Flow Rate 40 L/min

- Click to View more

Industrial Liquid Transfer Pump Price And Quantity

- 01 Set

- 15000.00 INR/Set

Industrial Liquid Transfer Pump Product Specifications

- 20 meters

- Manual

- -10C to 80C

- Stainless Steel

- Electric

- Corrosion Resistant, Compact Design, Easy Installation

- 1.8 bar

- Centrifugal Pump

- <65 dB

- Industrial Liquid Transfer

- 1.8 bar

- Gravity / Vacuum Suction

- 25 mm

- ISO 9001:2015

- 0.75 kW

- 6-8 meters

- Self-priming

- 40 L/min

- Liquid Transfer Pump

- 40 L/min

- Base Mounted

- 25 mm / 25 mm

- Chemical, Water, Oil, Solvents

- 2800 rpm

- 50 Hz

- Mechanical Seal

- 220-240 V

- Single-stage

Industrial Liquid Transfer Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Our top grade Liquid Transfer Pumps are the leading choice of many experts in the prestigious pumping industry. The impressive ability to move liquids with speed of our exceptional transfer pumps make them the most reliable in the market. The pumps are capable of transferring any sort of liquid from a point to another, for example: from a pipeline to tanks. The low maintenance requirements and minimal repair cost of our quality accredited Liquid Transfer Pumps have made the famous in the marketplace. The premium grade finish of our defect free pumps also contributes to their popularity over the years.

Features

- Our pumps showcase a faultless performance at all times

- Our quality pumps have a robust and impact tolerant body

- Our pumps are backed with designs that fit the requirements of clients perfectly

- Our pumps are installed with top grade engines that are famous for their efficiency

Specification

| Capacity | Up to 2200 m3/hr |

| Head | Up to 150 mtr |

| Temperature | 350 Deg C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 15 kg / cm2 |

| Discharge Size | 25 mm to 300 mm |

High Efficiency and Durability

This liquid transfer pump is constructed from premium stainless steel, making it resistant to corrosion and wear. Its closed impeller and high-quality mechanical seal guarantee minimal leakage and optimal performance, ensuring long service life for extensive industrial use. With a discharge pressure of 1.8 bar and head up to 20 meters, it easily handles challenging transfer tasks.

Versatile Industrial Applications

Specifically designed for transferring a variety of liquids, this pump accommodates applications in chemical processing, water treatment, oil movement, and handling solvents. Its broad working temperature range (-10C to 80C), self-priming capability, and compact design ensure adaptability and reliable operation in diverse industrial contexts.

Reliable and Safe Operation

Equipped with an IP55-protected motor and Class F insulation, the pump offers high safety standards and consistent operation. Its manual control system and base-mounted design provide ease of installation and maintenance, while the noise level remains below 65 dB for a quieter work environment.

FAQs of Industrial Liquid Transfer Pump:

Q: How is the industrial liquid transfer pump installed and operated?

A: Installation is straightforward due to its base-mounted, compact design. Connect the inlet and outlet (both 25 mm), ensure a stable power source (220-240 V, 50 Hz), and use manual controls to begin operation. The self-priming feature simplifies the start-up process.Q: What types of liquids can this pump handle in industrial settings?

A: This pump is suitable for transferring chemicals, water, oils, and various solvents. Its stainless steel construction and corrosion-resistant design make it compatible with a wide range of fluids commonly found in industrial or processing environments.Q: When is this pump most beneficial to use?

A: It is especially beneficial when reliable, continuous liquid transfer is needed in industrial processes, such as during chemical dosing, fluid loading/unloading, or water circulation, thanks to its durable design and steady performance.Q: Where can this pump be installed for optimal performance?

A: Install the pump in a well-ventilated, dry area with secure mounting to a stable base. It should be positioned where easy access to the inlet/outlet connection and power supply (220-240 V) is available, ideal for industrial plants, chemical facilities, or manufacturing installations.Q: What is the process for maintaining the pump to ensure a long service life?

A: Regularly check the mechanical seal, ensure unobstructed inlet/outlet flow, and verify the integrity of the electric connections. Periodic inspections of motor protection (IP55) and impeller condition help maintain optimal performance.Q: How does the pumps self-priming capability benefit users?

A: Self-priming enables the pump to automatically evacuate air from the suction line, reducing manual intervention and downtime. This feature ensures swift and efficient startup, even when the suction pipe is not completely filled with liquid.Q: What are the main advantages of choosing this model for industrial liquid transfer?

A: Key advantages include its high flow rate (40 L/min), energy-efficient 0.75 kW operation, mechanical sealed closed impeller for reliability, compliance with ISO 9001:2015 standards, low noise output (<65 dB), and its ability to handle a range of aggressive fluids due to robust stainless steel construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free