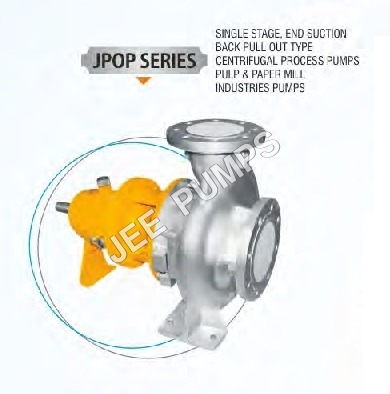

Industrial Paper Pulp Mill Pump

Product Details:

- Frequency 50/60 Hz

- Theory Centrifugal Pump

- Head Size 15 125 meters

- Fuel Tank Capacity N/A (Electric Pump)

- Speed 1450/2900 RPM

- Max Suction Up to 8 meters

- Discharge Pressure Up to 16 bar

- Click to View more

X

Industrial Paper Pulp Mill Pump Price And Quantity

- 01 Set

Industrial Paper Pulp Mill Pump Product Specifications

- 5.5 kW to 250 kW

- Self Priming / Non-Self Priming

- Up to 120C

- 50 2500 m/h

- Up to 8 meters

- Up to 16 bar

- Up to 2500 m/h

- 1450/2900 RPM

- 15 125 meters

- Centrifugal Pump

- Cast Iron / Stainless Steel

- N/A (Electric Pump)

- Paper Pulp Mill, Slurry Transfer

- 50/60 Hz

- Electric Driven

- End Suction

- 75 dB(A)

- ISO 5199 / DIN 24256

- DN65 DN300

- DN65 to DN300

- 380V / 415V

- Mechanical Seal / Gland Packing

- Industrial Paper Pulp Mill Pump

- Up to 16 bar

- Horizontal Base Mounted

- Corrosion resistant, Low maintenance, High Efficiency, Robust design

- Automatic / Manual

- Horizontal, Single Stage

- Pulp & Paper Industry, Chemical Processing

Industrial Paper Pulp Mill Pump Trade Information

- 50 Set Per Month

- 1 Week

Product Description

With our vast industrial experience we are serving a wide range of Pulp Mill Pump in the industry. Our Paper Pulp Mill Pump has a long service life and gives a pleasant performance to the user. They are based on the modern technology in compliance with the highly advanced machinery and equipment.

Features :-

- Corrosion resistance

- High durability

- High strength

Technical Specification

Capacity | Up to 1200M3/hr |

Head | Up to 55 Mtr. |

Discharge Size | 25 mm to 300 mm |

Temperature | Up to 250oC |

Speed | Up to 1500 rpm |

Pressure | Up to 5.5 kg/cm2 |

Impellers | Open & Semi Open type |

Consistency | Up to 7% |

M.O.C. | C.I, C.S., SS-304 / 304L, SS316 / 316L |

| Bronze, Alloy-20, CD4MCU Hast alloy B & C, etc... |

Applications :

- Chest pump

- Refiners pump

- Fan pump

- Centri cleaner pump

- Back water pump

- Separator pump

- Couch pit pump

- Turbo feed pump etc...

Efficient and Versatile Pumping Solutions

Designed for the pulp and paper industry, this centrifugal pump offers high performance across a range of applications. With multiple impeller options and the ability to handle varying pulp consistencies, it meets the rigorous demands of slurry transfer and process fluids handling. The robust construction, long-life wet parts, and low noise operation add significant value for industrial operations.

Built for Durability and Low Maintenance

Manufactured with high-strength alloy steel shafts and available in corrosion-resistant cast iron or stainless steel, the pump provides outstanding service longevity. Heavy-duty bearings, advanced sealing solutions, and optimized design minimize downtime and reduce maintenance costs, making it ideal for continuous, demanding work environments.

Adaptable to Diverse Industrial Needs

The pumps design accommodates various operational requirements, including direct coupling or belt-driven drives, multiple mounting options, and customizable color and voltage. Its compatibility with automatic or manual controls and a wide range of capacities ensures seamless integration into existing and new installations. Export-standard packing guarantees safe global delivery.

FAQs of Industrial Paper Pulp Mill Pump:

Q: How does the impeller type affect the pumps performance in pulp processing?

A: The choice of open, semi-open, or closed impeller allows adaptation to different consistencies and fiber sizes in pulp. Open and semi-open impellers are best for handling fibrous slurries, reducing clogging and ensuring efficient flow, while closed impellers are suited to cleaner liquids and provide higher efficiency at specific operational points.Q: What maintenance practices help ensure the long service life of this pump?

A: Routine inspection and lubrication of heavy-duty bearings, periodic seal checks (whether mechanical or gland packing), and monitoring for any abnormal vibrations or noise will extend the lifespan of the pumps wet parts and reduce downtime. Choice of grease or oil lubrication and robust construction also minimize maintenance needs.Q: When should I use mechanical seal versus gland packing?

A: Mechanical seals are preferred for operations requiring minimal leakage and greater containment, offering enhanced safety and lower maintenance, especially at higher pressures and temperatures. Gland packing, while slightly more maintenance-intensive, remains a cost-effective solution for less demanding sealing needs.Q: Where can this pump be installed for optimal efficiency?

A: The pump should be installed on a horizontal, stable base close to the pulp source or slurry sump to minimize suction lift and ensure reliable priming. Ensure ambient temperatures are within -10C to 50C and environmental conditions support the selected drive and control system.Q: What processes and industries benefit most from using this pulp mill pump?

A: This pump excels in pulp and paper mills for pulp transfer, dilution, and bleaching processes. It is also highly effective in chemical processing and industrial slurry applications where reliability, resistance to corrosion, and consistent flow are critical.Q: How does the pump handle variable operating conditions, such as temperature and pressure?

A: Engineered for flexibility, the pump operates effectively at temperatures up to 120C and discharge pressures up to 16 bar. The use of high-strength materials and advanced sealing systems ensures safe, leak-free performance across a wide range of demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Pulp & Paper Mill Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM