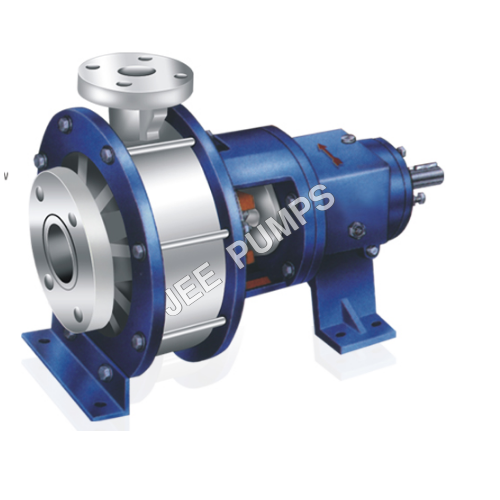

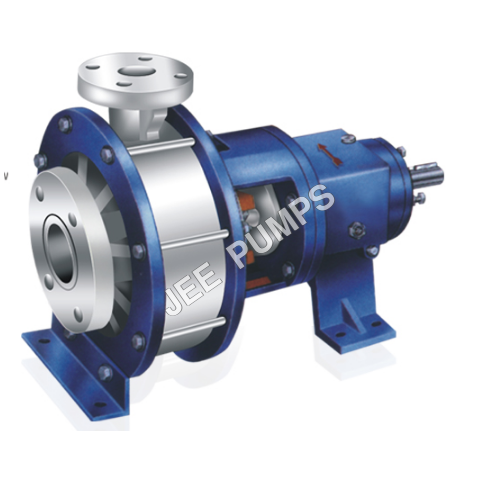

Industrial Polypropylene Centrifugal Pump

Product Details:

- Noise Level Low (<70 dB)

- Frequency 50 Hz

- Head Size 12 meter

- Discharge Pressure 1.2 bar

- Caliber 32 mm / 25 mm

- Working Temperature Up to 80C

- Mounting Type Base Mounted

- Click to View more

Industrial Polypropylene Centrifugal Pump Price And Quantity

- 12100.00 INR/Set

- 01 Set

Industrial Polypropylene Centrifugal Pump Product Specifications

- Manual

- 2900 rpm

- 220V / 380V

- 8 m/h

- Polypropylene

- Industrial Chemical Transfer

- Standard Atmospheric

- 1.1 kW

- Centrifugal Pump

- Mechanical Seal

- Self-priming

- 8 m/h

- Single Suction

- ISO 9001:2015

- 1.2 bar

- 12 meter

- Electric

- Low (<70 dB)

- 50 Hz

- Base Mounted

- Acid, Alkali & Chemical Liquids

- Up to 80C

- 32 mm / 25 mm

- 5 meter

- 1.5 inch / 1.25 inch

- Corrosion Resistant, Non-metallic Construction

- Single Stage

- Centrifugal

Industrial Polypropylene Centrifugal Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Our premium grade Polypropylene Centrifugal Pumps are the most acclaimed options available in the marketplace. They are carefully designed to fit the diverse demands of clients, the designs and size of the pumps can be customized to meet their expectations. Our Polypropylene Centrifugal Pumps are famous in the global marketplace for having uniquely high quality, which beats every other alternates available in the market. The premium grade finish and defect free bodies of our corrosion resistant centrifugal pumps also attracts a huge customer base towards our range. One can order bulk quantities of our pumps in exchange of reasonable prices at all times.

Features

- Our pumps have no physical, mechanical or operational defects

- All the pumps are quality tested prior to their sale

- The pumps are famous for having great impact tolerance

- Our pumps requires close to zero maintenance and repair

Specification

| Pressure | Up to 5 kg / cm2 |

| Head | Up to 45 mtr |

| Type | Centrifugal |

| Temperature | 80 to 140 Deg C |

| TDH Head | Up to 64 mtr |

| Speed (at 60 hz) | 1750 / 3500 rpm |

| Speed (at 50 hz) | 1440 / 2880 rpm |

Superior Chemical Resistance for Industrial Use

Built using non-metallic, corrosion-resistant polypropylene, this centrifugal pump excels in aggressive chemical environments typical of industrial settings. The SS 316 shaft further bolsters durability against harsh substances, making it ideal for acid, alkali, and various chemical liquid transfer applications. It meets ISO 9001:2015 standards, offering trusted reliability for distributors, exporters, and manufacturers.

Optimal Performance and User-Friendly Operation

Delivering up to 8 m/h flow at a 1.2 bar discharge pressure, this self-priming pump maintains a low noise profile while handling solid particles up to 4 mm. Its manual control system and flanged connections ensure straightforward integration into existing plant configurations. Simple horizontal base mounting and air-cooled design make installation and maintenance efficient.

FAQs of Industrial Polypropylene Centrifugal Pump:

Q: How does the polypropylene centrifugal pump handle aggressive chemicals?

A: The pump uses a robust, chemically-resistant polypropylene body and an SS 316 shaft, allowing it to safely and efficiently handle acids, alkalis, and various corrosive substances in industrial applications.Q: What types of industries and processes can utilize this pump?

A: This pump is suitable for any industry requiring the transfer of acidic, alkaline, or chemical liquids, including chemical processing, water treatment, pharmaceuticals, and industrial manufacturing.Q: When is it necessary to use a closed-type impeller with mechanical seal in chemical transfer applications?

A: A closed-type impeller with a mechanical seal is essential when dealing with volatile or hazardous chemicals, as it minimizes leakage and maintains pressure, ensuring safe and efficient fluid handling.Q: Where should the pump be installed for optimal performance?

A: The pump is designed for horizontal base mounting, ideally located near the liquid source at or below inlet level, ensuring efficient priming and minimizing suction lift for up to 5 meters.Q: What is the process for maintaining or servicing the pump?

A: Regular inspection of the mechanical seal, impeller, and motor bearings is recommended. The air-cooled and non-metallic design simplifies cleaning and corrosion checks, with easy access due to the flanged connections.Q: How can users benefit from the self-priming and low-noise features?

A: The self-priming design reduces downtime by quickly establishing flow without manual priming, while the low noise output (<70 dB) creates a safer and more comfortable working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM