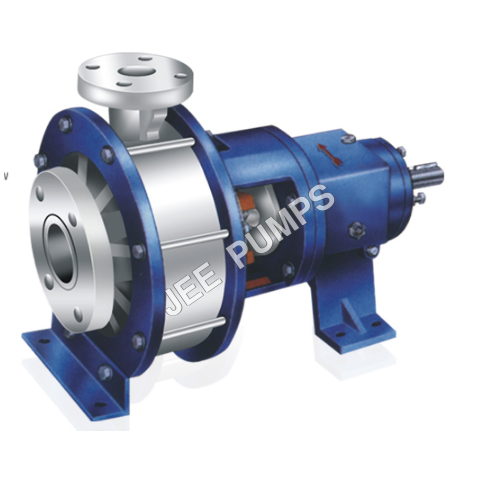

Industrial Tanker Uploading Pump

Product Details:

- Frequency 50 Hz

- Control System Manual/Electric Panel

- Theory Centrifugal Pump Theory

- Inlet/Outlet 2 inch / 2 inch (DN50/DN50)

- Working Temperature -10C to 80C

- Max Suction 6 meters

- Discharge Pressure 2.8 Bar

- Click to View more

Industrial Tanker Uploading Pump Price And Quantity

- 01 Set

- 4500.00 INR/Set

Industrial Tanker Uploading Pump Product Specifications

- 2.8 Bar

- Positive Displacement Suction

- 6 meters

- 40-60 m/hr

- Industrial Tanker Unloading/Uploading

- Mechanical Seal

- 1.5 ~ 3.0 Bar

- Corrosion Resistant, Heavy Duty, Easy Maintenance

- 15-40 meters

- 380V / 415V AC

- 50 mm

- 2900 RPM

- Base Plate Mounted

- Cast Iron / Stainless Steel

- <80 dB

- Oil, Water, Chemical Tankers

- 50 Hz

- 25000-35000 L/hr

- Manual/Electric Panel

- Horizontal Pump

- ISI / ISO 9001:2015 certified

- Electric

- -10C to 80C

- Centrifugal / Self-Priming

- Self-priming

- 3.0 - 5.5 kW

- 2 inch / 2 inch (DN50/DN50)

- Centrifugal Pump Theory

Industrial Tanker Uploading Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

We offer Tanker Unloading Pump to be used at the storage terminals for serving as the midstream for receiving and distributing crude oil via pipeline. However, crude oil is not the only fluid that can be used for the transportation. It can be used for a wide range of light end hydrocarbons and other heavy fuel oils. Moreover, the innovative pump design provided by us has made sure that the application of this pump efficient and safe. Use of Tanker Unloading Pump is one of the most cost effective solutions to eliminate the need of costly fume scrubbers that otherwise would have caused a lot.

Advantages

- Smooth finishing, compact design and sturdy construction make it fit for modern buyers.

- An ideal choice for avoiding all the leakages for longer run.

- Highly economical and simple to maintain.

- Great capability of pumping fluid continuously.

Specification

| Discharge Size | 25 mm to 40 |

| Head | Up to 60 m |

| Capacity | Up to 8 m3 /hr |

| Temperature | 110 deg C |

| Speed | Up to 1440 RPM |

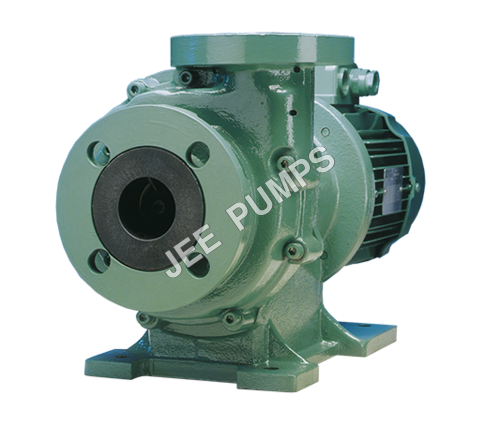

Optimized for Industrial Tankers

This pump is expertly designed for loading and unloading tankers transporting fluids such as water, oil, and chemicals. Its 2-inch inlet and outlet (DN50), combined with a significant flow rate and head lift, ensure quick and effective material transfer. The heavy-duty construction, available in cast iron or stainless steel, withstands harsh industrial conditions and frequent use, making it particularly well-suited for fleet operations and distribution centers.

Superior Build and Safety Standards

Enjoy peace of mind with an IP55-rated enclosure, TEFC cooling system, and Class F insulation. These features protect the motor from dust, water ingress, and overheating, ensuring safe daily operations. Certified to ISI and ISO 9001:2015 standards, this pump combines consistent performance with strict conformity to international quality regulations, reflecting a commitment to reliability and operator safety.

Designed for Longevity and Easy Maintenance

Minimize downtime with a shot-blasted or powder-coated finish to resist corrosion, along with mechanical seals and self-priming capabilities that ensure smooth start-up every time. The pumps horizontal, base-plate-mounted structure and user-friendly control system (manual or electric panel) further simplify both installation and ongoing maintenance, securing dependable service over the long term.

FAQs of Industrial Tanker Uploading Pump:

Q: How does the impeller type affect the performance of the Industrial Tanker Uploading Pump?

A: The pump offers both closed and semi-open impeller options, allowing efficient handling of varying liquid viscosities and solids content. Closed impellers improve efficiency with clean liquids, while semi-open impellers are better for slightly contaminated fluids.Q: What protection and insulation features ensure the pumps safety during operation?

A: With a protection level of IP55, the pump is shielded from dust and moderate water jets. The TEFC design prevents motor overheating, and Class F insulation allows reliable operation under demanding temperature conditions.Q: When is this tanker uploading pump ideal to use in industrial operations?

A: This pump is best used for swift loading or unloading of tankers carrying oil, water, or chemicals, especially where reliable flow rates (4060 m/hr), long service life, and corrosion resistance are essential.Q: Where can the Industrial Tanker Uploading Pump be installed?

A: The pump is designed for base plate mounting in industrial settings such as chemical plants, oil depots, and tanker loading or unloading stations. Its robust build enables both indoor and semi-outdoor installations.Q: What is the process for starting and maintaining this pump?

A: Start-up is straightforward with its self-priming design and positive displacement suction. Regular checks of mechanical seals, inlet/outlet connections, and removal of debris are recommended for optimal performance and longevity.Q: How does the pump benefit users in terms of maintenance and reliability?

A: Users benefit from easy maintenance due to its accessible mechanical seal system, shot-blasted or powder-coated finish preventing corrosion, and a design built for heavy-duty, consistent use, minimizing unplanned downtime.Q: What applications can this pump handle and what are its material options?

A: The pump is suitable for oil, water, and chemical transfer from tankers and is available in either corrosion-resistant cast iron or stainless steel to suit a wide range of industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM