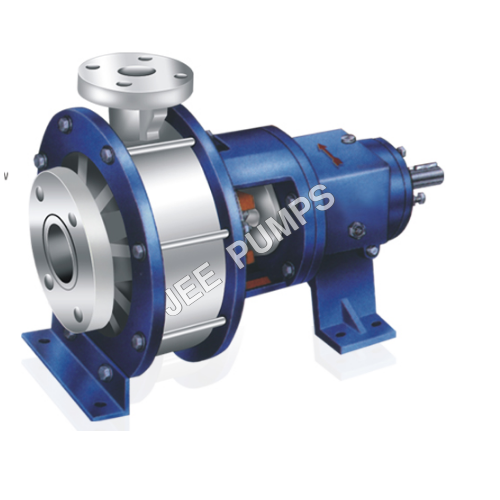

Industrial Non Metallic Pump

Product Details:

- Voltage 220-240 V / 380-415 V / Customizable

- Discharge Pressure Up to 6 kg/cm

- Noise Level <70 dB

- Mounting Type Horizontal Foot Mounted

- Frequency 50 Hz / 60 Hz

- Head Size 10 m to 45 m

- Control System Manual / Automatic

- Click to View more

Industrial Non Metallic Pump Price And Quantity

- 12000.00 INR/Set

- 01 Set

Industrial Non Metallic Pump Product Specifications

- 3 m/h to 60 m/h

- Standard as per model

- 2 kg/cm to 6 kg/cm

- 25 mm to 100 mm

- 0.5 HP to 10 HP

- Monoblock / Back Pull Out

- Non-Metallic Centrifugal Pump

- 1440 rpm / 2880 rpm

- Mechanical Seal / Gland Packing

- Centrifugal Pump

- Corrosion Resistant, Leak Proof, Maintenance Free

- Up to 5 meters

- 10 m to 45 m

- Polypropylene (PP), PVDF, FRP, UHMW-PE

- Horizontal Foot Mounted

- 50 Hz / 60 Hz

- -10C to 80C

- Chemical, Pharmaceutical, Water Treatment, Effluent Handling

- Manual / Automatic

- 3 m/h to 60 m/h

- Electric

- Industrial, Chemical Transfer, Acid & Alkali Handling

- 220-240 V / 380-415 V / Customizable

- ISO 2858 / DIN 24256

- Flooded/Negative Suction

- Self/Non Self Priming

- <70 dB

- Up to 6 kg/cm

Industrial Non Metallic Pump Trade Information

- 50 Set Per Month

- 1 Days

Product Description

Excellent functioning of our Non Metallic Pump is a result of employing latest manufacturing methods. Since we believe in quality being really essential of every product, we ensure that the quality standards of our product are well maintained. And, for this reason, we quality check our offered pump over different quality parameters. As the name implies, it is non metallic in nature and this allows it to perform with utmost excellency. The rigid construction of our Non Metallic Pump ensures it withstand wide range of working conditions. For instance, continuous working hours, etc. Moreover, it is fairly prices to provide clients the best value of their money.

Features

- Its innovative design matches with the latest requirements of the industrial applications.

- Cost effective solution for transferring a variety of fluids.

- Eliminates all the chances of frequent maintenance requirements.

- Better than ever performance even at lower power consumption.

Specification

| Capacity | Up to 50 m3 /hr |

| Head | Up to 49 mtrs |

| Size | 25 mm to 50 mm |

| Temperature | 80 deg C |

| Speed | Up to 3500 RPM |

| Pressure | Up to 5 kg / cm2 |

| Material of Construction | PP,P.V.D.F.,UHMWPE |

High Chemical Resistance for Demanding Environments

Our non-metallic centrifugal pumps are constructed from advanced polymers such as PP, PVDF, FRP, and UHMW-PE, making them highly resistant to a wide range of corrosive substances. This ensures safe and efficient handling in industries like chemicals and pharmaceuticals, drastically reducing the risk of metal corrosion and leakages. These materials also extend operational lifespan and reliability under continuous duty cycles.

Versatile Design with Multiple Customization Options

Choose from closed or semi-open impeller designs, with priming options (self or non-self), and several mounting configurations including monoblock or back pull-out structures. The pump supports a variety of inlet/outlet sizes (25 mm to 100 mm), varying voltage ranges, and can be provided in different colors as per client requests. With flexible connection typesflanged or threadedinstallation across diverse industrial setups is effortless.

Advanced Features Prioritizing Safety and Efficiency

Each unit is engineered for continuous operation and features protection classes IP54/IP55 and insulation classes F/H. The pumps mechanical seal or gland packing options ensure leak-proof performance, while the pressure rating up to 6 kg/cm and flow rate capacity of 3 m/h to 60 m/h meet various process requirements. Low noise (<70 dB) and maintenance-free construction contribute to safe, efficient work environments.

FAQs of Industrial Non Metallic Pump:

Q: How is the Industrial Non-Metallic Pump installed and where can it be used?

A: The pump is designed for horizontal foot mounting and can be installed with either flanged or threaded connections, based on your site requirements. Its suitable for use in chemical factories, pharmaceutical plants, water treatment facilities, and effluent management systems where resistance to aggressive fluids is essential.Q: What materials are used in the construction of the pump, and what benefits do these offer?

A: The pump is manufactured from high-grade Polypropylene (PP), PVDF, FRP, or UHMW-PE. These non-metallic materials offer exceptional corrosion resistance, chemically inert properties, and long service life, even when handling corrosive acids, alkalis, or solvents.Q: When should I choose a closed impeller versus a semi-open impeller design?

A: Closed impellers are ideal for clean liquids and provide higher efficiency, while semi-open impellers are suitable for handling slurries or fluids containing suspended solids. The choice depends on the nature of the fluid you intend to transfer or process.Q: What is the typical maintenance process for this pump?

A: Maintenance requirements are minimal due to the pumps corrosion-resistant and leak-proof construction. Routine inspection of the mechanical seals or gland packing and checking the motor and insulation class are recommended to ensure longevity and consistent performance.Q: How does the protection and insulation class affect pump operation?

A: The pump offers IP54/IP55 protection against dust and water ingress, with insulation classes F or H for motor windings. This ensures reliable operation in harsh industrial environments and enhances motor longevity even under continuous duty cycles.Q: What are the advantages of using this pump for industrial chemical transfer?

A: By utilizing non-metallic materials and robust sealing systems, the pump is highly reliable for transferring aggressive chemicals. It offers durability, resistance to leaks, and reduced maintenance, minimizing operational downtime and ensuring worker safety.Q: How customizable are the operational specifications like voltage, color, and control system?

A: The pump supports voltage options from 220-240 V to 380-415 V and can be tailored for specific requirements. Colors can be set to blue, grey, or as per client preference, and it is available with either manual or automatic control systems to fit your operational processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free