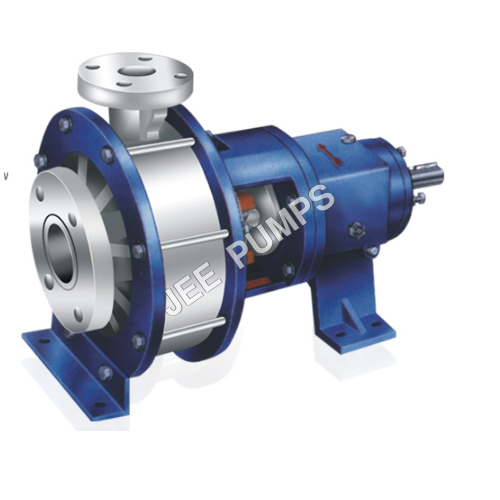

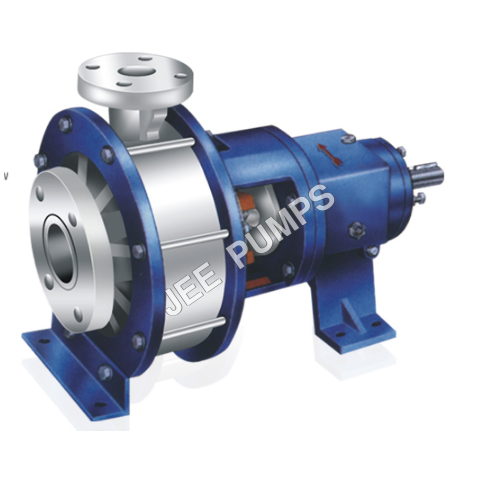

Corrosion Resistant Polypropylene Centrifugal Pump

25000 INR/Piece

Product Details:

- Control System Manual / Automated

- Voltage 220-415V

- Features Corrosion-resistant, Maintenance Free, Non-metallic Construction, High Efficiency

- Flow Rate 3 to 40 m/hr

- Discharge Pressure Up to 2.8 Bar

- Working Temperature -10C to 70C

- Mounting Type Base Mounted

- Click to View more

X

Corrosion Resistant Polypropylene Centrifugal Pump Price And Quantity

- 25000 INR/Piece

- 1 , , Piece

Corrosion Resistant Polypropylene Centrifugal Pump Product Specifications

- Single Stage

- Horizontal Centrifugal Pump

- 50/60 Hz

- Transfer of corrosive chemicals, Acid handling

- 5 meters

- 25 mm / 25 mm

- 3 to 40 m/hr

- Up to 28 meters

- Centrifugal Pump

- 25 mm to 50 mm

- Polypropylene (PP)

- Self Priming & Non-Self Priming options

- 2900 rpm

- Below 75 dB

- Mechanical Seal

- Single Suction

- 0.5 HP to 7.5 HP

- -10C to 70C

- Base Mounted

- Electric

- 3 to 40 m/hr

- Up to 2.8 Bar

- Chemical Industries, Electroplating, Effluent Treatment Plants, Water Treatment

- ISI, ISO 9001:2015

- Corrosion-resistant, Maintenance Free, Non-metallic Construction, High Efficiency

- Manual / Automated

- 220-415V

- Up to 2.8 kg/cm

Corrosion Resistant Polypropylene Centrifugal Pump Trade Information

- 1 , , Piece Per Day

- 1 Days

Product Description

Discover the ravishing power and rarefied performance of our Corrosion Resistant Polypropylene Centrifugal Pump, acclaimed with favorable reviews across industries. Commanding a robust construction, this pump boasts semi-open/closed impeller types, versatile motor phases, and supports both flanged and threaded connections. The limited time offer is perfect to buy online and upgrade your fluid-handling capability. Lightweight yet durable at 18 kg, this model delivers up to 40 m/hr at 2.8 bar, making it the preferred choice for chemical, electroplating, and water treatment professionals. Experience efficiency, reliability, and maintenance-free operation at its finest.

Direction Of Use, Application Areas, and Type Of Usage

The Corrosion Resistant Polypropylene Centrifugal Pump is designed for seamless integration into various industrial systems. For optimal performance, ensure the correct priming optioneither self-priming or non-self-primingdepending on your installation. Its command extends to chemical transfer, acid handling, and water treatment duties. Use it in continuous or intermittent operations across chemical industries, effluent treatment plants, and electroplating units. Always verify the max solid handling and suitable temperature range for your specific application.

Domestic Market Presence, Sample Policy, and Delivery Logistics

Our pumps command recognition throughout Indias main domestic market, with efficient supplier and distributor networks ensuring timely availability. Prospective buyers can request product samples, offering a hands-on introduction with minimal initial expenditure. Swift delivery is guaranteed through coordinated freight and goods transport partners, optimizing both cost and delivery times. Benefit from streamlined order fulfillment and transparent logistics, allowing you to manage project deadlines and shipping expenditures effectively.

Direction Of Use, Application Areas, and Type Of Usage

The Corrosion Resistant Polypropylene Centrifugal Pump is designed for seamless integration into various industrial systems. For optimal performance, ensure the correct priming optioneither self-priming or non-self-primingdepending on your installation. Its command extends to chemical transfer, acid handling, and water treatment duties. Use it in continuous or intermittent operations across chemical industries, effluent treatment plants, and electroplating units. Always verify the max solid handling and suitable temperature range for your specific application.

Domestic Market Presence, Sample Policy, and Delivery Logistics

Our pumps command recognition throughout Indias main domestic market, with efficient supplier and distributor networks ensuring timely availability. Prospective buyers can request product samples, offering a hands-on introduction with minimal initial expenditure. Swift delivery is guaranteed through coordinated freight and goods transport partners, optimizing both cost and delivery times. Benefit from streamlined order fulfillment and transparent logistics, allowing you to manage project deadlines and shipping expenditures effectively.

FAQs of Corrosion Resistant Polypropylene Centrifugal Pump:

Q: How do I select between self-priming and non-self-priming options for this pump?

A: The choice depends on your installation layout and operating conditions. Self-priming versions are ideal when the pump is positioned above the liquid source, facilitating easy start-up. Non-self-priming configurations suit scenarios where the pump is flooded or liquid flow is gravity-assisted.Q: What are the main benefits of this corrosion resistant polypropylene centrifugal pump?

A: Key advantages include robust chemical resistance, maintenance-free and non-metallic construction, high efficiency, and a versatile range suitable for handling corrosive chemicals, acids, and wastewater with commanding reliability.Q: When can I expect delivery after placing an order online?

A: Standard delivery times range from a few days up to two weeks, depending on stock availability and your location. Our streamlined freight and goods transport processes help expedite shipments with minimal expenditure on your part.Q: Where is this centrifugal pump most commonly used?

A: It sees wide application in chemical industries, electroplating lines, effluent and water treatment plants, where corrosion resistance and effective solid handling are essential for process reliability.Q: What is the process for requesting a product sample?

A: To request a sample, simply contact our sales team or submit an inquiry via our online platform. Samples are provided at a nominal cost, allowing you to evaluate product suitability before making a larger expenditure.Q: How does the pump handle solid particles and what is its limit?

A: This model is engineered to manage solids up to 5 mm in size, making it suitable for specific industrial processes involving small suspended particles while maintaining stable flow and efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Polypropylene Pumps' category

"We do not entertain inquiries from resellers."

Download Brochure

Download Brochure  Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free